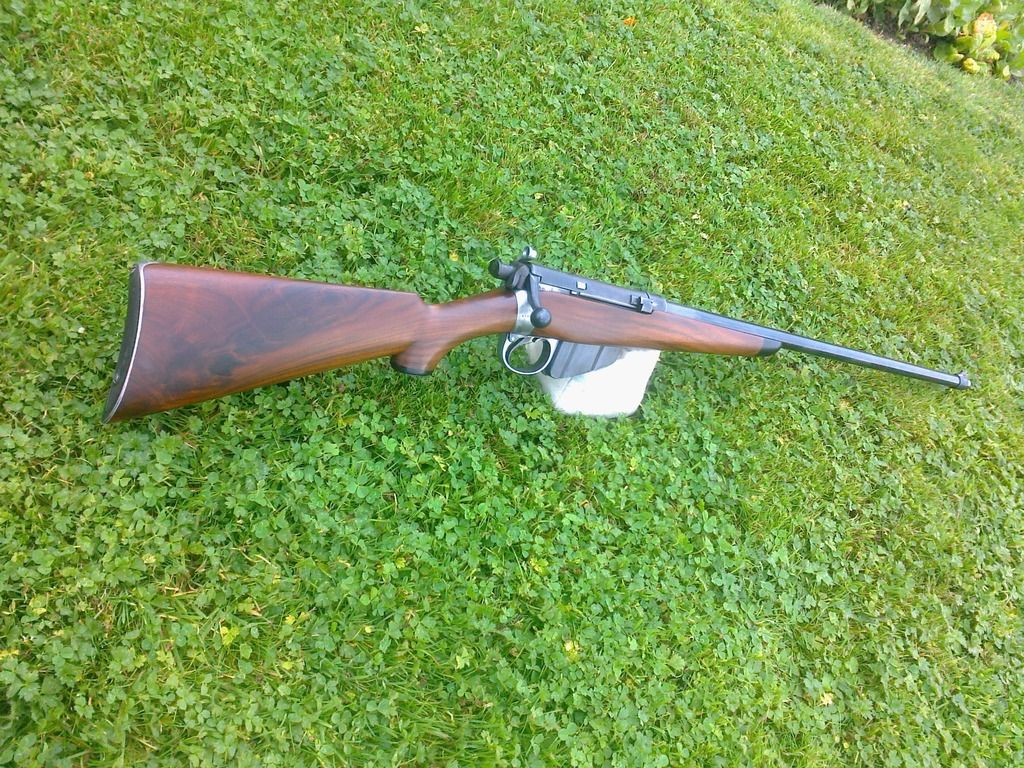

TOTW checkered steel butt plates were fitted so I set to on the buttstocks and got some shape into them. Will not be able to do much more now till there are a couple of barrels threaded up.

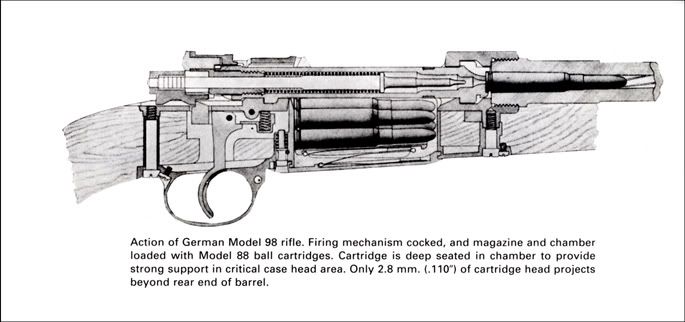

As for the barrel I had got onto one that was a take-off and had been chambered for the a shortened 405 Winchester --the 405 x 2.2. It had been fitted to a Marlin Lever action so needed som work on it. Thr action thread was turned off and a sleeve was machined up and threaded onto it. One downside was that it had two dovetail cuts on the underside and one for the front sight. I had ordered a reamer to lengthen the chamber but had to keep in mind the Lee Enfield magazine length. I decided to cut the chamber to 2.410 and trim 405 Winchester brass to 2.405 and with the cast bullet I intended to use I could load to a COAL of 3 inches. It would also suit a jacketed bullet.

To fix - hide the dovetails a piece of steel was filed to shape and tapped into the first one

The second one was treated the same way

As for the barrel I had got onto one that was a take-off and had been chambered for the a shortened 405 Winchester --the 405 x 2.2. It had been fitted to a Marlin Lever action so needed som work on it. Thr action thread was turned off and a sleeve was machined up and threaded onto it. One downside was that it had two dovetail cuts on the underside and one for the front sight. I had ordered a reamer to lengthen the chamber but had to keep in mind the Lee Enfield magazine length. I decided to cut the chamber to 2.410 and trim 405 Winchester brass to 2.405 and with the cast bullet I intended to use I could load to a COAL of 3 inches. It would also suit a jacketed bullet.

To fix - hide the dovetails a piece of steel was filed to shape and tapped into the first one

The second one was treated the same way

Comment