After reading all the opinions I think the way to go is using the clamshell , reaction rod, and barrel vise at the same time.

Have you ever heard of bending an Upper receiver?

Collapse

X

-

Clamshell and rxn rod would be sufficient for barrel installation.

Barrel vise if changing muzzle device.

Why not have a reaction rod with 2 flats milled, so you could put an open end wrench on it?

Have the clamshell clamped in the vice, then use the reaction rod and an open end wrench to counter act torque created by friction between flange and barrel nut.

I think it is over kill, but if you are trying to get a loctited barrel off it might be a thought.

Comment

-

-

Someone knowing nothing about AR's might read this thread and come to the conclusion that they are the biggest POS ever.

Perhaps I'm just lucky I don't know, but I have removed and installed several barrels using both methods and have yet to damage anything.

I have yet to meet one with Loctite though, and I'm sure that would make a difference.

When the pin shears does it damage the receiver?

Comment

-

-

Meet Loctite.LOL

That pic is of an AA upper I had to bust down for a rail and other stuff. I broke two wrenches on that one IIRC. I was pretty pissed. I felt damn near certain I'd snap the upper receiver extension off, but I got lucky.

Sometimes a sheared pin goes with a damaged notch, and sometimes not.

ETA: for anyone new to ARs--- The AR definitely isn't a P.O.S. It's just so widely popular there are umpteen million parts for it, from many, many suppliers. There are many different techniques people apply also, and sometimes parts and techniques collide.LOLLast edited by Variable; 08-22-2014, 12:32 PM.Life member NRA, SAF, GOA, WVSRPA (and VFW). Also member WVCDL. Join NOW!!!!!

We either hang together on this, or we'll certainly HANG separately.....

Comment

-

-

Really for typical barrel install and removal, the clamshell and or LRRFP52's cutting board picture, will do fine. The reaction rod is fine as well by itself. Both methods take one component of the torque out of the equation.

I believe for stubborn or loctited barrels, the protocol is to use some heat to break it loose.

Comment

-

-

Many moons ago a friend of mine torqued his barrel nut as hard as he could with out using any grease, anti seize, or oil on his first Olympic arms build. Years later he removed his barrel and sections of the upper receiver threads pulled away. The barrel stud was fine as was the slot for the barrel stud on the upper receiver. I would have junked the upper at that moment but he decided to use it and mount another barrel on it. He doesn't shoot it a lot and uses it as a beat around pickup gun. I would never trust this upper and is the example why I would never purchase a Franken gun unless I knew the builder was competent.

Comment

-

-

-

The magpul block looks like it would combine the advantages of the reaction rod and some aspects of the ones that hold the receiver. IE: It should keep major torque off the index pin/notch as it appears to prevent the upper from rotating as well.

Given it's polymer I wonder how much flex, but I'm not in the 80lbs of torque camp so it could be OK... I torque to a minimum then additional torque enough to align the gas tube.

Thinking about it, seems like a reaction rod type could have an insert made for the receiver that you'd secure with a pin. Do the same thing, keep the receiver from rotating.

Comment

-

-

+1

The fact that it secures the upper to prevent it from rotating with the torque stresses seems like a good plan. I personally don't see the use of polymers in the construction as a source of concern, since it appears the component with the steel lugs is embedded, and likely adds to the overall stiffness. It's too bad the BCG is employed for longitudinal stabilization, though, as that precludes using a surrogate gas tube to facilitate easier indexing of the barrel nut. At $50, it is quite tempting.

The armorer's tool seems to be solid, as well, but $80 for a wrench seems high to me.

You mean something like this?Thinking about it, seems like a reaction rod type could have an insert made for the receiver that you'd secure with a pin. Do the same thing, keep the receiver from rotating.

An insert would require the reaction rods have something for the insert to work against. A ridge or protrusion on the rod of some sort would need to be machined or welded for that insert to provide additional counter torque.Last edited by NugginFutz; 09-01-2014, 07:18 PM.If it's true that we are here to help others, then what exactly are the others here for?

Comment

-

-

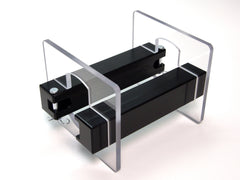

Just stumbled across this and thought it was pretty comparable to a clamshell vise. And reasonably priced! A little more versatile than a clamshell vise too. What do ya'll think? Is it worth it?

CNC cut NO-M.A.R® polymer protects receivers finish. Install and remove barrels that fit 223 AR15 flat top receivers. Works with bolt group and handle installed or removed. Works in bench vises that open 4 inches wide. Use horizontally to remove or install barrels. Use vertically for cleaning and hand-guard removal. Use on your bench top for easy manipulation. Full width blocks support receiver when using small vise. Includes 2 patented Anti Torque Plates for easy handling. Heavy duty design helps remove stubborn barrels without risk!Last edited by burkew23; 09-27-2014, 04:35 AM.

CNC cut NO-M.A.R® polymer protects receivers finish. Install and remove barrels that fit 223 AR15 flat top receivers. Works with bolt group and handle installed or removed. Works in bench vises that open 4 inches wide. Use horizontally to remove or install barrels. Use vertically for cleaning and hand-guard removal. Use on your bench top for easy manipulation. Full width blocks support receiver when using small vise. Includes 2 patented Anti Torque Plates for easy handling. Heavy duty design helps remove stubborn barrels without risk!Last edited by burkew23; 09-27-2014, 04:35 AM.

Comment

-

-

I don't know. Just looking at it--- During barrel procedures it appears to place the force against the takedown lugs (normally bad) and makes up for it by also bearing some of the load against the top rail. That might be okay if they work together equally. If the fit isn't good it could be bad though. Hard to say (IMO) without actually giving it a hands on trial.Originally posted by burkew23 View PostJust stumbled across this and thought it was pretty comparable to a clamshell vise. And reasonably priced! A little more versatile than a clamshell vise too. What do ya'll think? Is it worth it?

http://www.plastixrevolution.net/pro...ver-vise-block

Certainly cheap enough. It might work well, or it might break off a receiver lug if you really reef on it. Someone will have to be a guinea pig (not me). Life member NRA, SAF, GOA, WVSRPA (and VFW). Also member WVCDL. Join NOW!!!!!

Life member NRA, SAF, GOA, WVSRPA (and VFW). Also member WVCDL. Join NOW!!!!!

We either hang together on this, or we'll certainly HANG separately.....

Comment

-

Comment