SAAMI barrels/bolts

Collapse

X

-

What ric said (and Vascar2 on several occasions!!).

SAAMI is the chamber, not the bolt/chamber combo. A chamber can be cut to space on a 0.125 depth bolt or on a 0.136 bolt.

Most of the - what I would call - good mfrs seem to use the 0.136 bolt so they use the "Type II" bolt face terminology, invented by Satern but nonetheless useful, to let you know that.

Biggest caveat is to make sure your barrel and bolt are matched as to head space dimensions, I personally agree with ric that the combo with 0.136 face is the better choice."Down the floor, out the door, Go Brandon Go!!!!!"

Comment

-

-

I feel your pain, Toehead. Like they say on some Facebook relationships, it's complicated.

After a manufacturing FUBAR (painful details can be found on threads on the forum), Satern started selling their barrels with what they called Grendel II chambers. The Grendel II has a parallel throat, rather than Alexander's compound throat. The parallel throat allows bullets to be seated longer than the SAAMI throat. I can get you a diagram of the difference if you're interested.

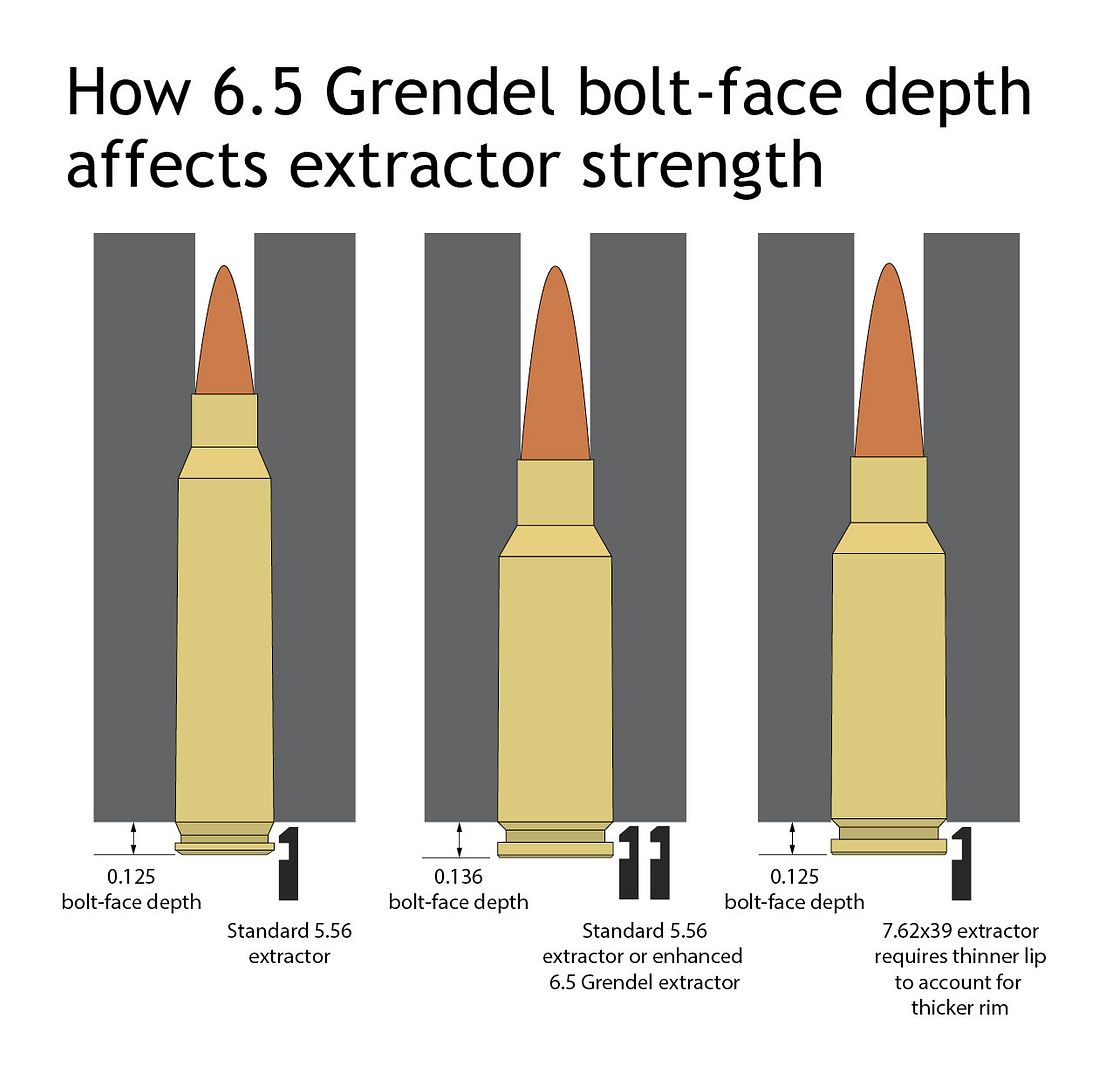

Type II versus Type I on the bolt design is a different deal. Alexander Arms designed the Grendel to use his .50 Beowulf bolt, which has a bolt face depth of 0.136", while the bolt face depth for 223/5.56 ARs is 0.125". For some unknown reason, Black Hole Weaponry (BHW) started calling bolts with 0.125" face depths Type I and they called the correct Grendel bolts Type II. Sadly, others in the industry have perpetuated this situation.

I would agree that your best bet is to select a barrel with the SAAMI 6.5 Grendel chamber and be sure it is cut to utilize a 0.136" bolt face.

Comment

-

-

Ok that helps. I was planning to get the GrendelHunter upper with a Toolcraft NiB BCG that is Type II but then I started getting confused again when I saw Faxon has a SAAMI chamber and others labeled theirs Type II. So if I understand both the Faxon barrel and GrendelHunter upper with Satern/Liberty barrel will work with the Toolcraft Type II BCG?

Comment

-

-

SAAMI as it refers to 6.5 Grendel

SAAMI only shows diagrams for minimum chamber and maximum cartridge. There are no call-outs for a specific action or bolt depth, since Grendel can be chambered in any number of actions.

For AR15s, there is a Grendel technical package that was developed by Bill A. which includes the bolt and chamber dimensions, as well as tighter specs for the barrel extension, after many years of extensive RDT&E.

This included using a deeper bolt face since the Grendel brass has very thick rims that require a different extractor geometry. The recess behind the extractor claw that allows the rim to fit has a wider circumference since the Grendel case is fatter.

This also requires changes to the extractor pin location on the bolt, as well as the extractor shelf height from the bolt's firing pin bore.

The radii around the bolt lugs are increased to make up for the lost lug root strength with the difference in depth between a .125" and .136" depth, and a very specific type of 9310 alloy is used for its properties in dealing with impact, thrust, and torsion.

The metallurgy is also tightly controlled if you want a long-lasting bolt, with destructive testing done in batch percentages, unlike the ill-conceived HPT testing of 5.56 bolts for the Mil TDP, which causes unnecessary micro fractures in the alloy that eventually propagate into failure modes, usually cracking the bolts at the cam pin hole (this is where I've broken real 5.56 bolts personally after high volume, compressed round counts).

History

After initial sales of 6.5 Grendel showed a lot of market opportunity and rigorous growth, companies who have zero business being in the AR15 market (even in 5.56) started offering knock-off 6.5 barrels and bolts, using whatever bolts they could find on the market at the time. One particular company was a well-known gunshow-grade outfit making rock-bottom priced parts kits that would leave your hands black after handling them, and they sourced the cheapest garbage bolts with .125" face depth they could find. These were incorrectly identified as "7.62x39" bolts at the time, though they had zero knowledge of Colt's actual funded work on the 7.62x39 AR15 Sporter. They called those barrel/bolt combos and uppers "6.5 Sporter". Those bolts would break within 20 rounds in some cases, as they were made from 8620 and with terrible heat treating with a barely-existent QC process.

Soon, the after-market started to wrongly accept that .125" face depth bolts were what to use with the growing demand for 7.62x39 AR15s, even though nobody seemed to care to research what Colt had done with that project. The .125" face depth x39 bolts quickly became the "standard" for the industry, tossing Colt's well-funded and researched efforts to the wind without even recognizing that they laid the groundwork for solving some of the challenges with stuffing a fatter case in the AR15. Before the 6.5 Grendel, Bill A. had already built the .50 Beowulf on the lessons that Colt had learned on their 7.62x39 rifle development program, so it was natural to use that bolt design for 6.5 Grendel.

Many well-intended and quality manufacturers simply accepted the .125" face depth at face value, including Black Hole Weaponry. Since they were already sourcing .125" face depth x39 bolts, they called those "Type I" for their internal use, and when they later offered .136" Grendel bolts, they called those "Type II".

For some reason, that BHW-internal term, "Type II", became widely-used in the industry. Think of it as someone coming along and re-naming your dog, even though you, all your family, and all your neighbors know the dog by their correct name.

Then you continue to see people refer to the dog by another name, even though their name never changed. That's the simplest way to explain the misconception and misnomer that is the "Type II" term.

Other manufacturers find it much easier to just say "Type II" than write what I've done above when referring to .136" face depth bolts. Anther overlooked aspect of bolts is the bolt overall length in order for it to be compatible with existing Mil-Spec 5.56 firing pins (Most of the AR15 firing pins on the market do not meet the Mil-Spec TDP because of materials selection and processes corner-cutting.). With a deeper face depth, you need the tail to be longer so you don't have excessive firing pin protrusion and pierced primers. Many companies that started to see why Grendel bolt faces are deeper just assumed that everything is the same, but it isn't, so some of have had to source and spec shorter firing pins, while others are still unaware of the basic mechanical engineering of firearms development and simply expect to ride the coat tails of AR15 modularity instead of proofing the system.

Competing Misnomers: Type II vs Grendel II

To add more confusion, one of the reamer makers who many manufacturers go to decided to create another chamber design that has no known standard other than what they say it is, and called it the "Grendel II". This was in response to barrel makers who wanted to run reamers as ragged as possible to get as much reamer life on them rather than use a new reamer, since sourcing reamers is a very common bottleneck for barrel makers. Once a finishing reamer is no longer cutting chambers to the SAAMI minimum, and making smaller throats, factory ammo starts to jam the lands. These barrels should have been finish-reamed with a new reamer, but in order to meet demand of inpatient customers, a lot of shops will cave, or drop the ball on QC when under market pressure. Everyone I know of has had this happen to them, and most handle it professionally.

The intent of the ill-conceived "Grumble II" chamber was to extend the throat out so that reamer life could be lengthened for customers looking to crank volume instead of hold themselves to the SAAMI spec. The first discussions I saw about the "Grumble II" indicated they wanted to use a 6.5x47 Lapua throat, which would have put the land engagement so far forward of maximum magazine COL, it would have trouble loading on a lead sled even. A simple look at the basic dimensional limitations of the AR15 would show even a small child that elementary math didn't seem to be used in contriving such a long throat for the AR15 (If your COL is longer than the inside of the mag well before we even factor in the box magazine, your math is not so good.). Given all the measurements taken here on the forum on barrels labeled "Grendel II", the actual land location has been all over the map, from way too short, to way too long. I personally avoid any barrels with that label, as I have yet to see any consistent accuracy from them.

For manufacturers, it's not worth your reputation to go with a poor performing chamber design that will rarely yield positive results for the customer just to get a few more cycles on a reamer. Since the SAAMI dimensions are open and quality reamers that have been inspected with optical comparators are readily available from several reamer makers, why one would go with an unknown makes little sense to me, unless you spec the reamer yourself for a specific load if you don't care about factory ammo compatibility or AR15 COL limits.

Summary: SAAMI only calls out minimum chamber and maximum cartridge so that we have compatible ammo and rifles.

6.5 Grendel bolts are their own unique parts, not labeled correctly under any other term.

Many reputable manufacturers use some of the common, but incorrect terms for 6.5 Grendel bolts to indicate .136" face depth.NRA Basic, Pistol, Rifle, Shotgun, RSO

CCW, CQM, DM, Long Range Rifle Instructor

6.5 Grendel Reloading Handbooks & chamber brushes can be found here:

www.AR15buildbox.com

Comment

-

-

I think I'm going to start using a model or "mark" nomenclature and call them Mk136 and Mk125 bolts. Just don't get it confused with Mk262 5.56 ammo!

Am still working on a project to get the "best of both worlds" using a Mk125 0.125 boltface depth WITH the necessary strengthened extractor. May not be possible, but we'll see. . . .:: 6.5 GRENDEL Deer and Targets :: 6mmARC Targets and Varmints and Deer :: 22 ARC Varmints and Targets

:: I Drank the Water :: Revelation 21:6 ::

Comment

-

-

To me:

Bolts are 'Grendel Standard' (1.36) or 'Shallow' (1.25).

Throats are 'SAAMI' or 'Extended'.

Extractors are 'Grendel Standard' or 'Short Nose'

Only way I can keep them straight."The best we can hope for concerning the people at large is that they be properly armed."

-- Alexander Hamilton, The Federalist Papers at 184-188

Comment

-

-

Ok, that really clears it up for me. I was getting confused between barrels and bolts. So the barrel should have the original SAAMI chamber by Alexander but the Grendel II works just as well by Saturn. The Type I bolt is too thin (based on the 7.62 extractor by BHW) to work with either so the Type II is the common bolt that works with both SAAMI and Grendel II chambers. Now that I'm clear I just ordered a 18" Faxon from the group buy thread.

Comment

-

-

I went through the same dilemma over a year ago when I decided I wanted a 6.5 Grendel. To be blunt there is a lot of crap out there calling itself 6.5 Grendel. After much reading here I decided to stick with a SAAMI chambered barrel from a reputable manufacturer and a .136" bolt, also from a reputable manufacturer. I have never regretted that decision.

At the moment I have 2 Grendels in the safe. One is an 18" LaRue, The other is a build based around a Proof Research 20" barrel on an Aero Precision Enhanced upper/hand-guard. Both are capable of outstanding accuracy and function great.Cliff

USN Ret., FPD Ret.

Nobody is coming. It's up to you.

Comment

-

-

Interesting. What's the idea if we have clearance to hear it? Perhaps an extractor beefed up at the end with more material sort of like a lug, or even more involved, a channel machined into the back of the barrel to accommodate a longer/stronger extractor that extends past the lugs?Originally posted by BluntForceTrauma View PostAm still working on a project to get the "best of both worlds" using a Mk125 0.125 boltface depth WITH the necessary strengthened extractor. May not be possible, but we'll see. . . .

Comment

-

Comment