I think I'm finally ready to start loading/reloading.

Here's my process (starting from once fired brass).

-Run cases through rotary tumbler

-Lube cases

-Resize/deprime

-Deep clean with SS media

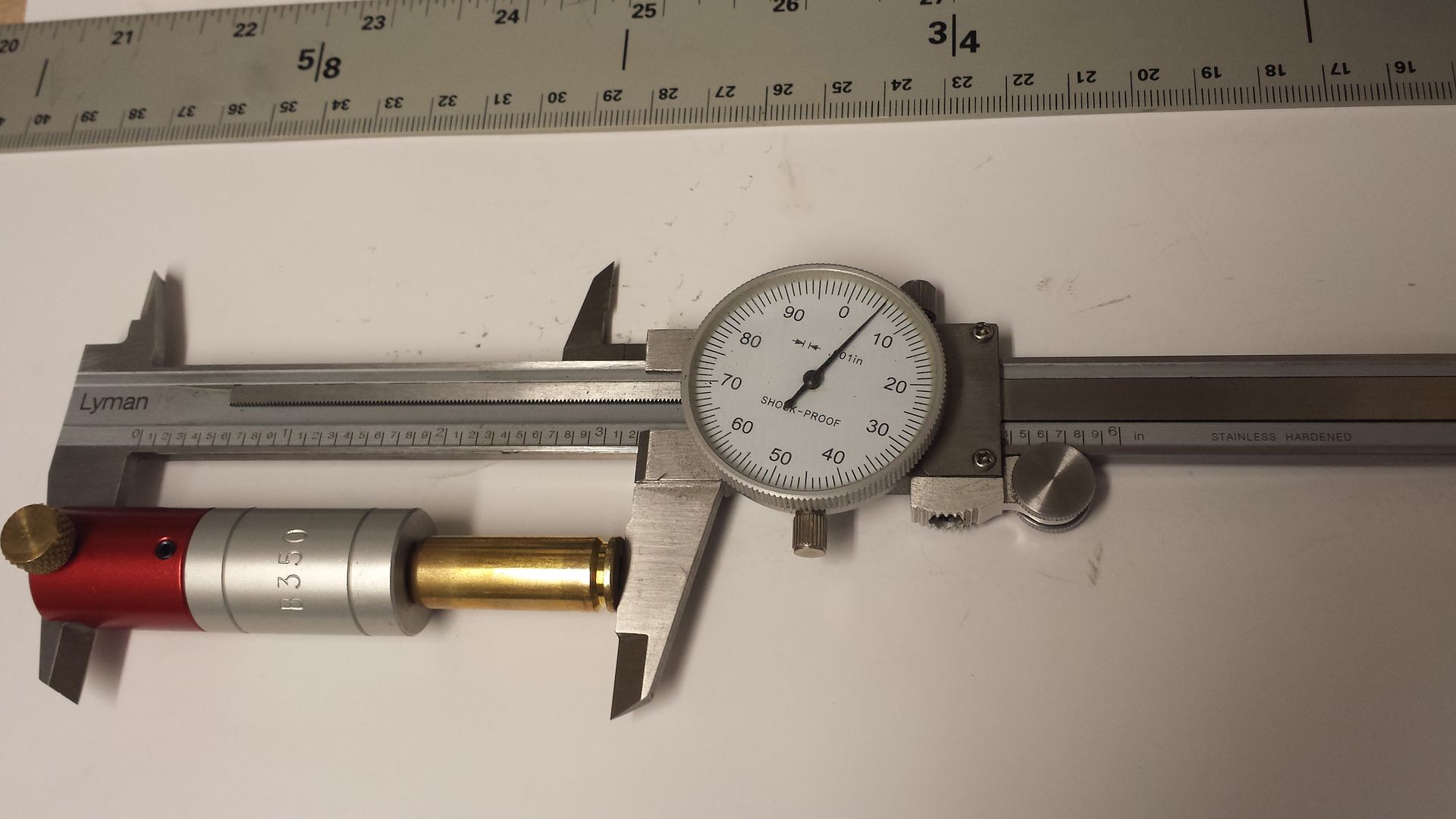

-Check case in Wilson case gauge

-Trim as necessary (length 1.515)

-Prime case

-Apply powder charge from chargemaster

-Seat bullet

-Factory crimp (shooting through AR)

-Lock, load, shoot, repeat.

Initial measurements:

Case length: 1.515

COL (measured to lands with Hornady checker).

123 AMAX-2.195

123 SMK-2.234

123 CC-2.185

So the only question I know to ask at this point is how much "jump" off the lands to apply? Should I start with the full length or start by backing off a bit?

Here's my process (starting from once fired brass).

-Run cases through rotary tumbler

-Lube cases

-Resize/deprime

-Deep clean with SS media

-Check case in Wilson case gauge

-Trim as necessary (length 1.515)

-Prime case

-Apply powder charge from chargemaster

-Seat bullet

-Factory crimp (shooting through AR)

-Lock, load, shoot, repeat.

Initial measurements:

Case length: 1.515

COL (measured to lands with Hornady checker).

123 AMAX-2.195

123 SMK-2.234

123 CC-2.185

So the only question I know to ask at this point is how much "jump" off the lands to apply? Should I start with the full length or start by backing off a bit?

Comment