With the new barrel I recently installed this was my initial 100yd group using Nosler 120gr BT and 4 loads of AR Comp in .3gr increments. My initial group was fair but I wanted to test dampening the barrel harmonics.

I had a scrap piece of honeycomb shaped synthetic rubber that was left over from mounting motor controllers on an engine room bulkhead (I work on oil field supply vessels). Due to the amount of vibration the installing technicians used this material to dampen vibration to the electronics.

It was a tight fit but I inserted the rubber between the end of the hand guard and the barrel.

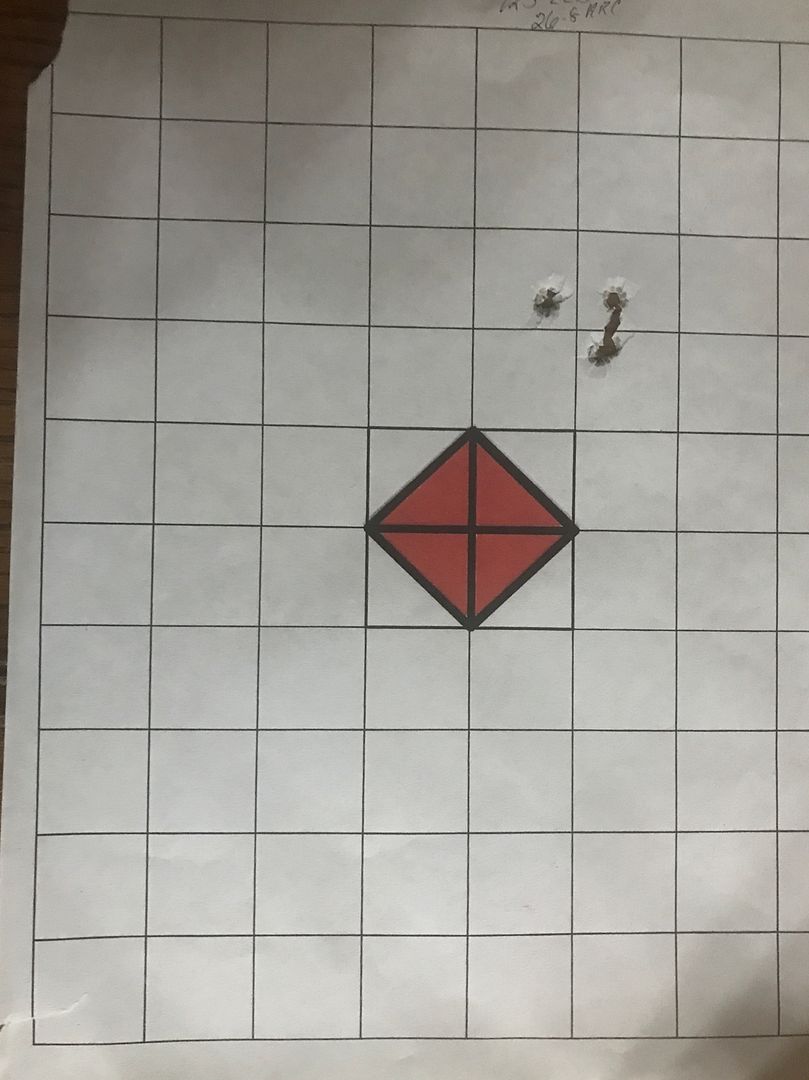

First group is without the dampening material.

Second group is with the material inserted in the hand guard. Due to barrel tension the shot about an inch higher but the same load tightened up substantially. This I think supports Lemonaid?s third method.

I had a scrap piece of honeycomb shaped synthetic rubber that was left over from mounting motor controllers on an engine room bulkhead (I work on oil field supply vessels). Due to the amount of vibration the installing technicians used this material to dampen vibration to the electronics.

It was a tight fit but I inserted the rubber between the end of the hand guard and the barrel.

First group is without the dampening material.

Second group is with the material inserted in the hand guard. Due to barrel tension the shot about an inch higher but the same load tightened up substantially. This I think supports Lemonaid?s third method.

[/URL

[/URL

Comment