Properly made Grendel bolts are no problem.

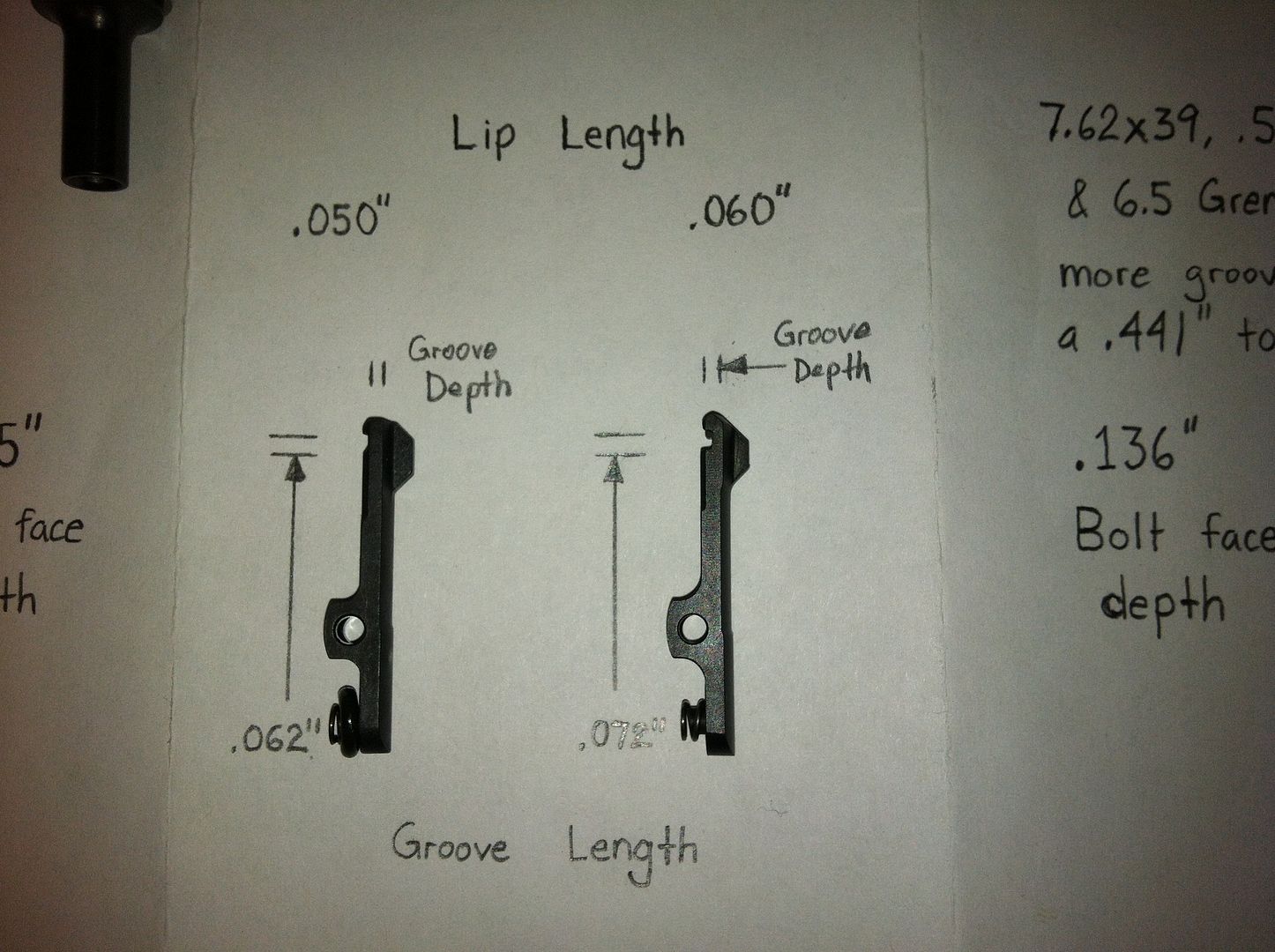

Grendel extractors...is another discussion...

Grendel extractors...is another discussion...

I'll call lake city for ya!

I'll call lake city for ya!  would love to see the US lead the way and be the best equiped. we owe it to those protecting... I hope Russia doesn't beat us to it. not a fan at all of .223/5.56 7n6 is considerably better IMO. nice to see a few new grendel ammo flavors from shotshow this year as well.

would love to see the US lead the way and be the best equiped. we owe it to those protecting... I hope Russia doesn't beat us to it. not a fan at all of .223/5.56 7n6 is considerably better IMO. nice to see a few new grendel ammo flavors from shotshow this year as well.

Comment