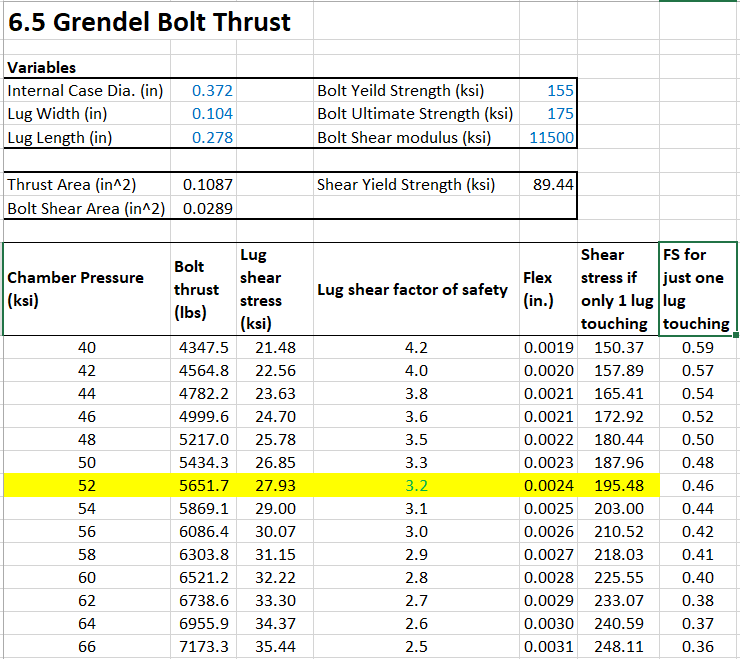

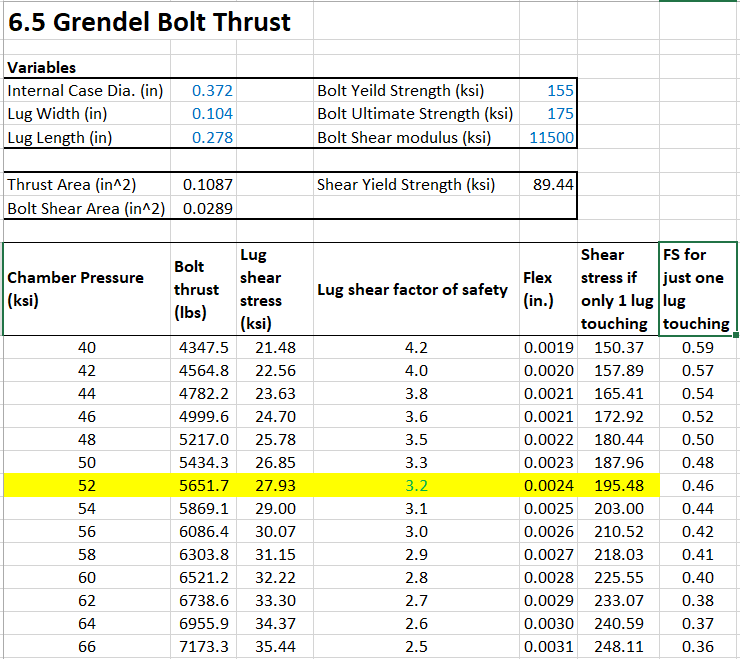

It seems like the topic of Grendel bolt strength, or lack thereof, comes up quite often in discussion threads. Discussions often center around bolt life, risk of lug breakage vs. load pressure, etc. I thought it might be useful to illustrate some basic solid mechanics calculations to illustrate expected bolt lug yield strength safety factor as a function of internal case pressure (and resulting bolt thrust).

Bottom line up front: With the assumption that all 7 bolt lugs are carrying the load evenly, the Grendel bolt design has a shear yield safety factor above 3.0 (Very healthy margin). If you assume only 1 lug is making contact due to poor dimensional tolerances, misalignment, etc., the shear load will exceed the yield and ultimate shear strengths and single lug failure would be expected.

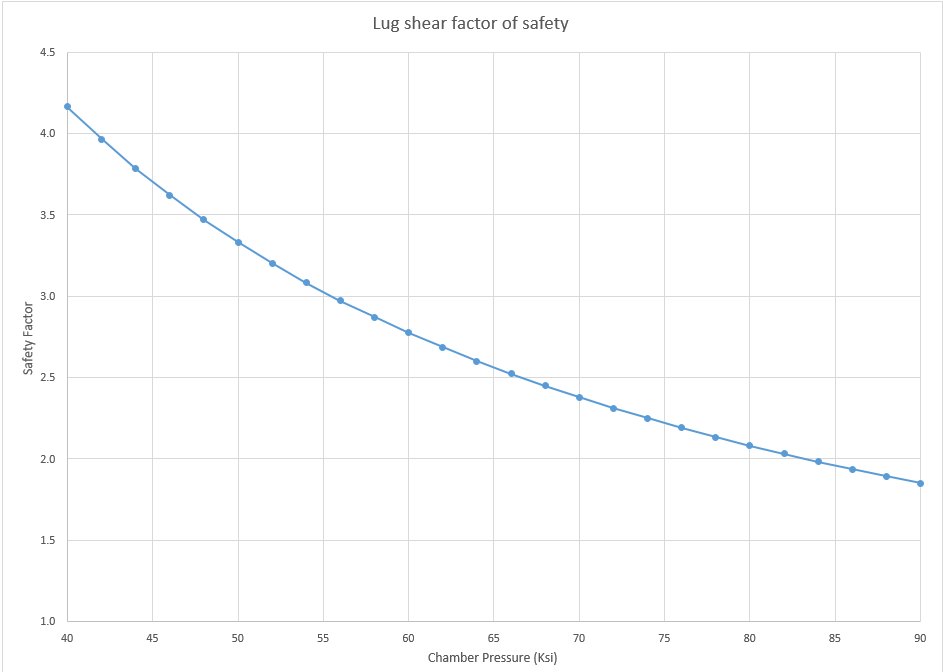

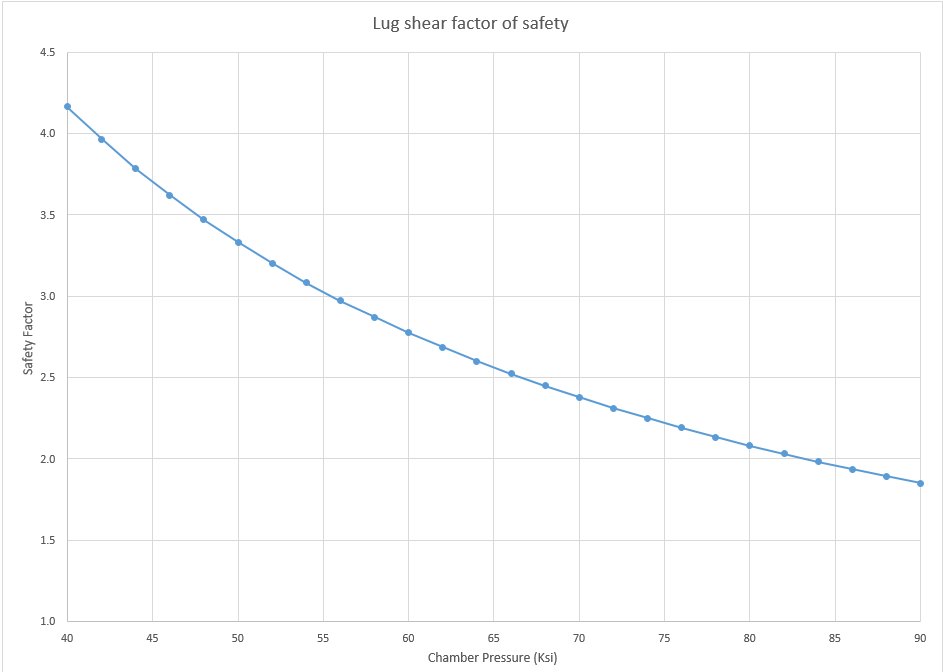

As can be seen from the data above, the Grendel as designed has a healthy safety margin against shear failure of the lugs. See the highlighted row corresponding to 52 Ksi chamber pressure with SF = 3.2. The calculations assume NO friction between the case and chamber wall, which would reduce bolt thrust and increase safety factor, so these calculations can be considered conservative for UNIFORM bolt contact. Increasing chamber pressure to 60 Ksi reduces SF to 2.8 but would NOT result in bolt lug failure for a single overloaded round (as expected for a robust design!).

In reality all bolt lugs will not contact uniformly and some will be loaded higher than others. That is one reason why the lugs near the extractor are often the weak link in the design. Cumulative fatigue damage at the lug roots over repeated loading could lead to fatigue failure of the lugs, but this should NOT happen for correctly dimensioned parts that are assembled in alignment to ensure approximate uniform contact. From looking at these calculations I would have to conclude that Grendel bolt lug failure can only results from:

1) uneven lug loading that overloads a single or pair of lugs. This could break a lug in short order over a small number of cycles.

2) Poor bolt metallurgy that leads to low strength OR brittle failure from loss of ductility (usually a heat treat problem)

3) Existing defect in the material that leads to fatigue crack growth and resulting failure.

Notice that SF is not a strong function of chamber pressure for reasonable loads. So no, you will not shear off a lug from running a single hot load unless there are some other underlying issues like 1-3 above. This is not to say that you should make a point of repeatly running "hot" loads. Higher chamber pressure does increase stress and will lead to an increased rate of fatigue failure.

As an interesting side note the "Flex" column is a rough estimate of elastic deformation of the bolt lugs during firing (about 0.002"). This is not permanent deformation like you see in the fired brass case. Instead this is an elastic displacement that "springs back" in place to zero deformation after firing.

Another interesting thought experiment for another time would be to consider the increased pressure dwell time for suppressed firearms. When running a suppressor the pressure drop in the chamber is delayed from the resistance from the suppressor baffles, so the bolt can be rotating to unlock while still supporting significant back thrust. The friction between the lugs and barrel extension would exhibit torsional stress in addition to the direct shear stress assumed below which would increase the overall lug stress and decrease safety factor.

I hope this post is found useful and can lend some context for future discussions of bolt failures. Feel free to double check my calculations as they were performed quickly with no QC.

Best,

PA

Bottom line up front: With the assumption that all 7 bolt lugs are carrying the load evenly, the Grendel bolt design has a shear yield safety factor above 3.0 (Very healthy margin). If you assume only 1 lug is making contact due to poor dimensional tolerances, misalignment, etc., the shear load will exceed the yield and ultimate shear strengths and single lug failure would be expected.

As can be seen from the data above, the Grendel as designed has a healthy safety margin against shear failure of the lugs. See the highlighted row corresponding to 52 Ksi chamber pressure with SF = 3.2. The calculations assume NO friction between the case and chamber wall, which would reduce bolt thrust and increase safety factor, so these calculations can be considered conservative for UNIFORM bolt contact. Increasing chamber pressure to 60 Ksi reduces SF to 2.8 but would NOT result in bolt lug failure for a single overloaded round (as expected for a robust design!).

In reality all bolt lugs will not contact uniformly and some will be loaded higher than others. That is one reason why the lugs near the extractor are often the weak link in the design. Cumulative fatigue damage at the lug roots over repeated loading could lead to fatigue failure of the lugs, but this should NOT happen for correctly dimensioned parts that are assembled in alignment to ensure approximate uniform contact. From looking at these calculations I would have to conclude that Grendel bolt lug failure can only results from:

1) uneven lug loading that overloads a single or pair of lugs. This could break a lug in short order over a small number of cycles.

2) Poor bolt metallurgy that leads to low strength OR brittle failure from loss of ductility (usually a heat treat problem)

3) Existing defect in the material that leads to fatigue crack growth and resulting failure.

Notice that SF is not a strong function of chamber pressure for reasonable loads. So no, you will not shear off a lug from running a single hot load unless there are some other underlying issues like 1-3 above. This is not to say that you should make a point of repeatly running "hot" loads. Higher chamber pressure does increase stress and will lead to an increased rate of fatigue failure.

As an interesting side note the "Flex" column is a rough estimate of elastic deformation of the bolt lugs during firing (about 0.002"). This is not permanent deformation like you see in the fired brass case. Instead this is an elastic displacement that "springs back" in place to zero deformation after firing.

Another interesting thought experiment for another time would be to consider the increased pressure dwell time for suppressed firearms. When running a suppressor the pressure drop in the chamber is delayed from the resistance from the suppressor baffles, so the bolt can be rotating to unlock while still supporting significant back thrust. The friction between the lugs and barrel extension would exhibit torsional stress in addition to the direct shear stress assumed below which would increase the overall lug stress and decrease safety factor.

I hope this post is found useful and can lend some context for future discussions of bolt failures. Feel free to double check my calculations as they were performed quickly with no QC.

Best,

PA

Comment