Is there any advantage to a finish other than black phosphate on a 6.5 Grendel bolt carrier assembly? Will be using a Lilja 20" AR740 barrel with direct impingement gas assembly. PF matched upper/lower. Will most likely use a standard A2 stock assembly but may use a carbine assembly if I can get it straightened out in my head what I will need to do to get it to work properly. Thank you, John

Finish on bolt carrier assembley

Collapse

X

-

Nevermind I searched around a bit and found their price list

Comment

-

-

-

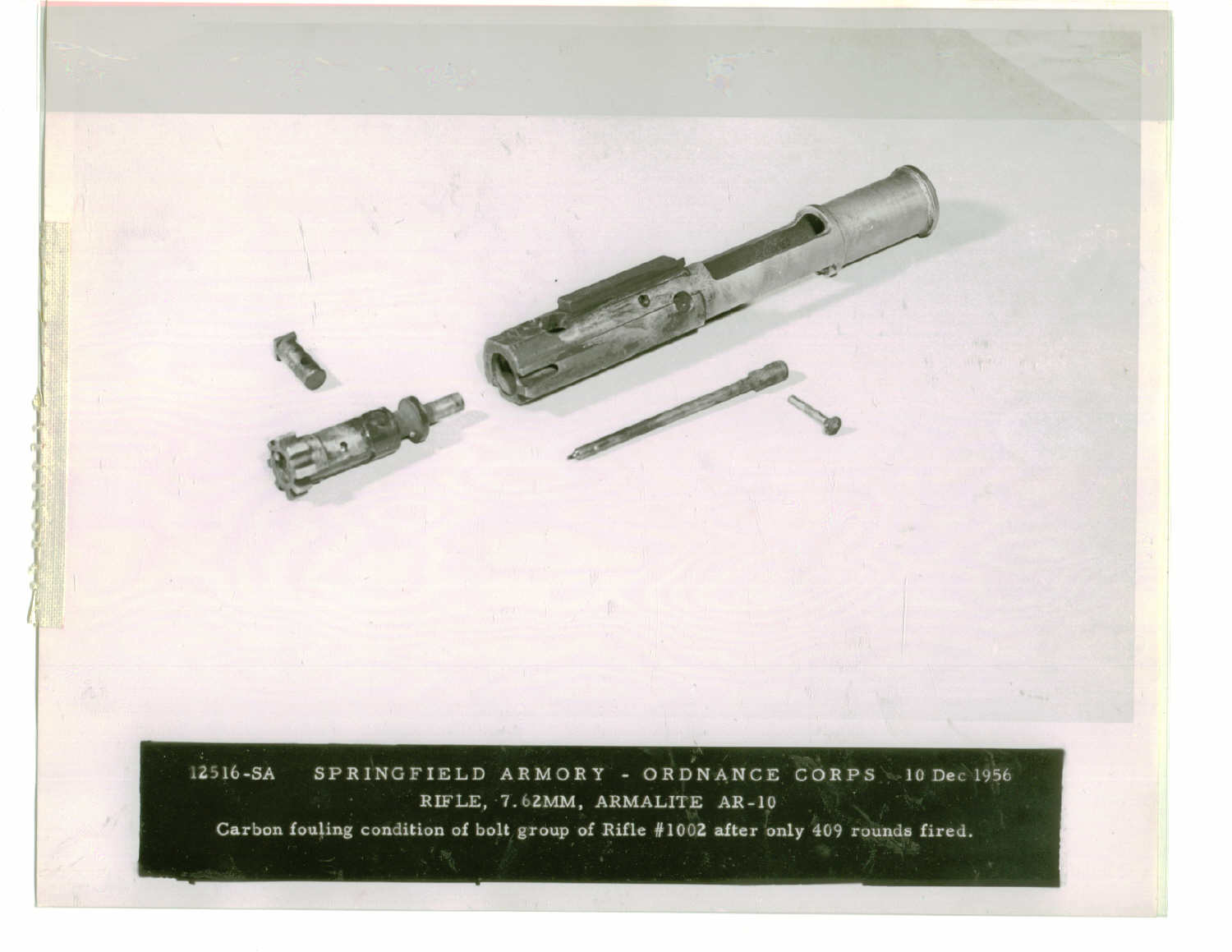

The original Stoner designs had hard chromed bolt carrier groups, starting with the prototypes leading up to the AR10 in production form, which had a hard chromed BCG.

The Army, in its feverish attempts to louse up the AR15, insisted on a phosphated BCG, but with chrome lining in key areas like the bore for the bolt, and inside the carrier key, as cost-saving measures, while adding more cost with the abortion that the forward assist assembly is.

In actual experience with all of them, ranging from original hard chrome BCG's, to TiN, to NiB and black nitrided units, I have yet to see a measurable performance difference, but I do like the feel of the black nitrided and NiB BCG's the best, followed by hard chrome and TiN. I've never had any real problems with true Mil-spec phosphated carriers though, but they are more prone to corrosion if not kept lubricated. The BCG should always have lubrication on it.

The other aspect of this that gets overlooked is the type of upper receiver and its coatings. Mil-spec calls for 7075 T6 Aluminum, Type III hard-coat anodized, with a Moly resin dry film lube baked on the inside of the upper receiver.

There is the argument that too hard of a surface on the bolt can cause issues with the barrel extension, if the extension is just 8620.

NP3 is an electroless Nickel with embedded PTFE (Teflon, polytetraflouroethylene), whereas NiB is an electroless Nickel with boron, forming columnar structures perpendicular to the substrate alloy. The surface shows up as rounded nodules, which reduces the amount of surface contact with the articulating piece, in this case, the upper receiver, the cam pin, the bolt, and the barrel extension.

For NiB bolts, it makes sense to have an NiB or black nitride barrel extension, so that the NiB nodules don't work-harden or wear the extension teeth in high volume. There are 4 generations or patent era for NiB, with the current one being Gen 4 if it is from Fail Zero, or EXO.

The safest route is to match the bolt plating material in the extension.

Comment

-

-

LRRPF52 have a question for you. You mention the coatings from UTC as being 4th gen. Are you familiar with the NiB coatings from WMD Guns? Do you know how it stacks up against the EXO from UTC? Kinda curious as both UTC and WMD are both in Stuart, Fl. If they might also be the same coating?

Comment

-

-

LRRPF52, Thank you for your reply. I have sent Mark at PF an email asking if they coat the barrel extensions that they use on their builds. That seems to be the only way to get a coated barrel extension, possibly. Certainly the barrels directly from Lilja are not coated? You answered exactly what I wanted to know and I really appreciate your sharing your knowledge and experience with us (me). John

Comment

-

Comment