Hey all,

I am continuing to enjoy my Grendel, put another 20rnds thru it yesterday dialing in new scope and mounts. I was less than stable so had to pull the sandbags out after 5 rounds being all over and seeming to not respond to turret adjustments..

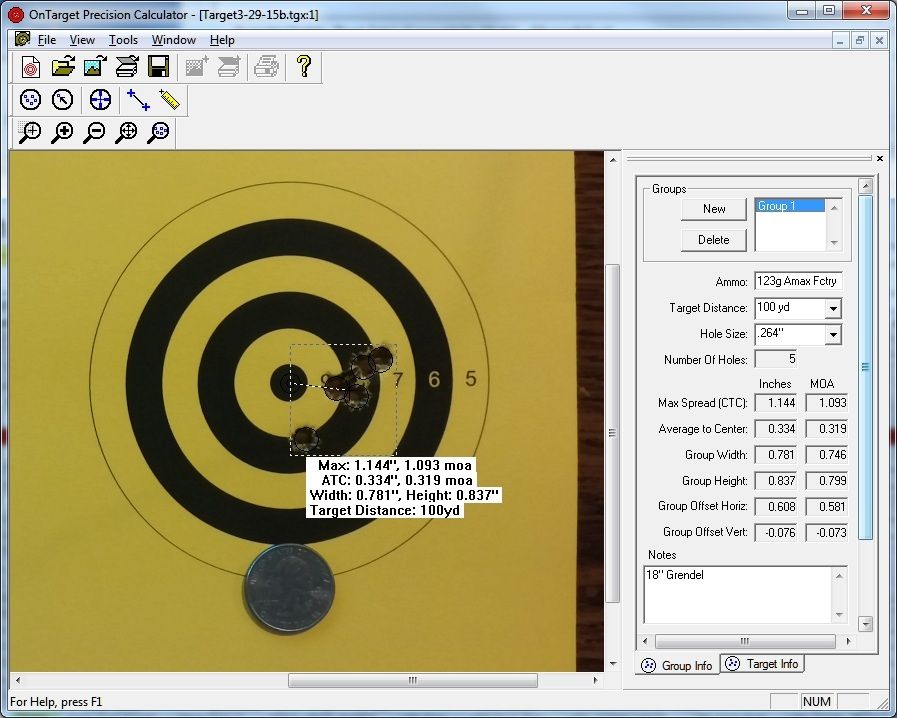

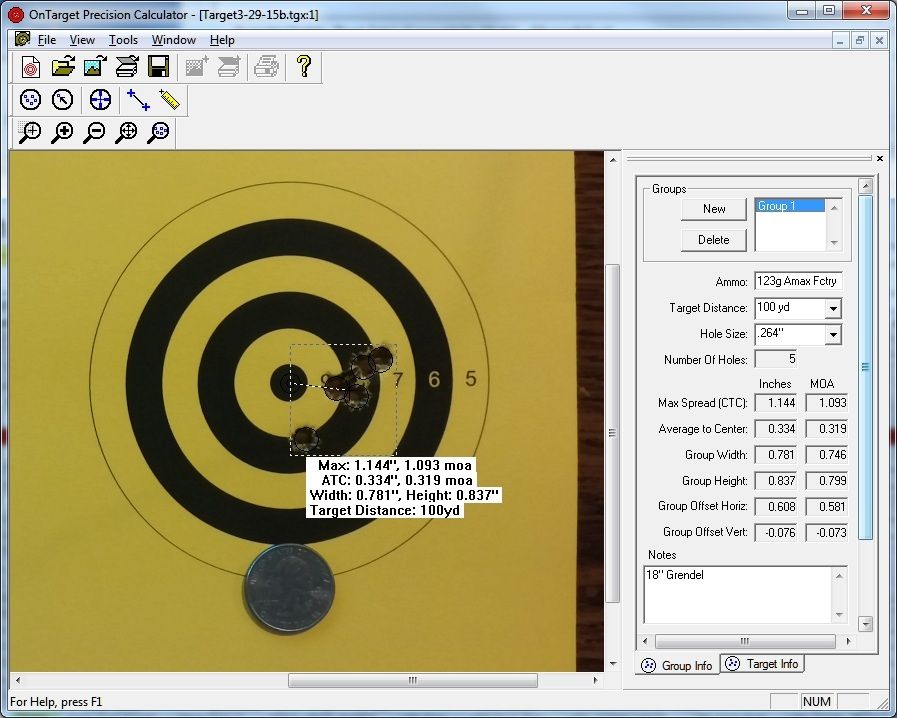

Ended the day with a decent 5 round group, was .527MOA until I jerked the last shot (always the case!!)

Now for my question. I noticed a few shots the gun jumped left a little, then putting the gun away I saw that my brake had loosened by about 1/8 a turn. I have a Killer Innovations brake.

How do you guys install your brakes, a certain torque? a drop of locktight? I am concerned about torquing it to much as I have heard that can distort the barrel/rifling.

I am continuing to enjoy my Grendel, put another 20rnds thru it yesterday dialing in new scope and mounts. I was less than stable so had to pull the sandbags out after 5 rounds being all over and seeming to not respond to turret adjustments..

Ended the day with a decent 5 round group, was .527MOA until I jerked the last shot (always the case!!)

Now for my question. I noticed a few shots the gun jumped left a little, then putting the gun away I saw that my brake had loosened by about 1/8 a turn. I have a Killer Innovations brake.

How do you guys install your brakes, a certain torque? a drop of locktight? I am concerned about torquing it to much as I have heard that can distort the barrel/rifling.

Comment