Here what I've amassed so far...I believe its everything I need except for BUIS (which I'm still on the fence about if I really need).

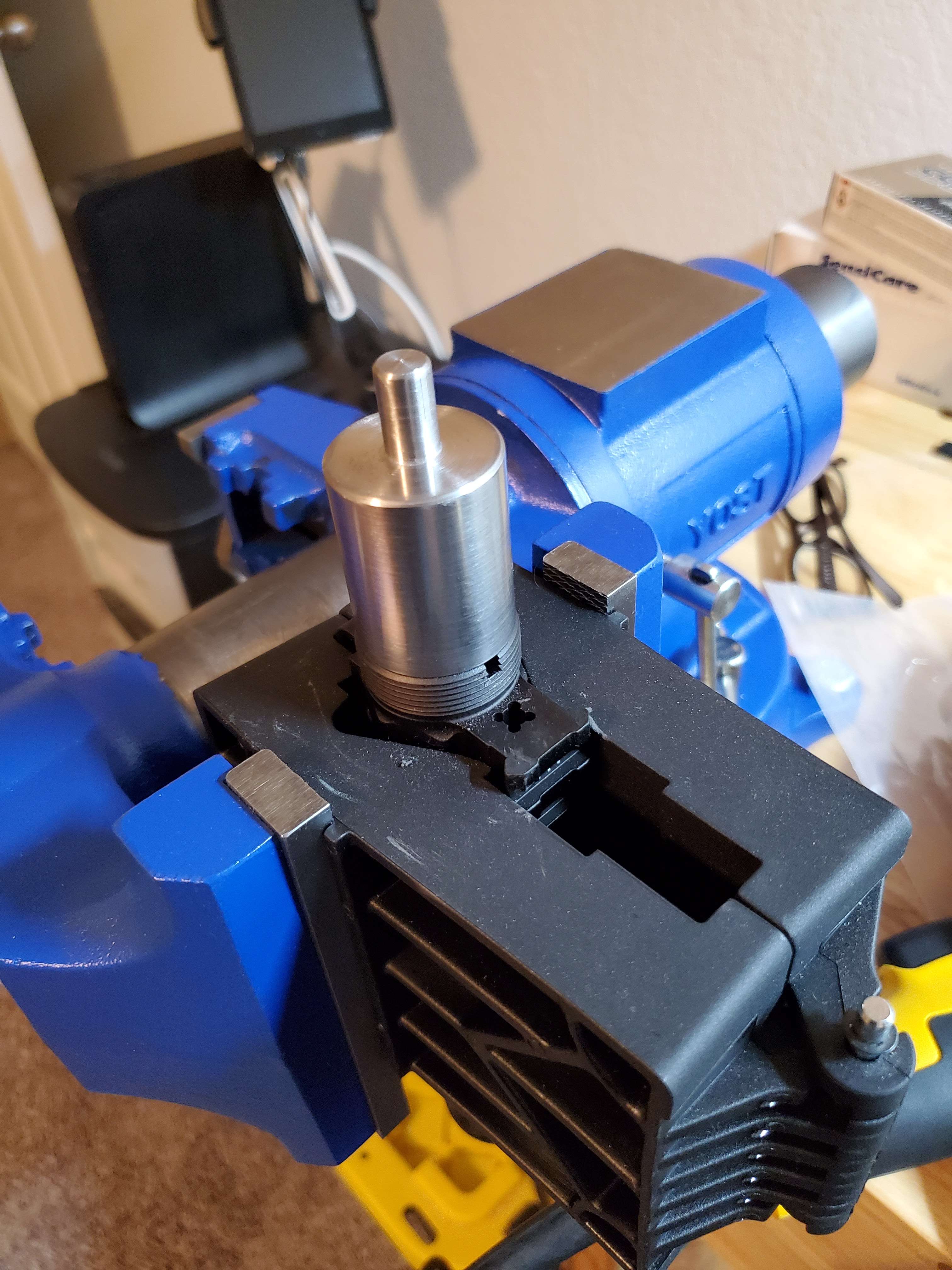

Thanks to Vortex's generous 40% discount for First Responders, even with the tools I needed to buy (bench vise, blocks, punches, torque wrench, armorers wrench, Reaction Rod) plus four E-Lander magazines and a Pelican 1750 to tote this thing around, I was able to stay under $5000. Now the fun part...I get to put it all together

Comments welcome.

- Aero Precision M4E1 Stripped Upper Receiver + Upper Parts Kit

- Aero Precision Gen 2 Stripped Lower Receiver + Geissele Lower Parts Kit

- Lilja AR24 23" 6.5G HBAR barrel

- APA Fat Bastard Gen-2 Self Timing Muzzle Brake

- Superlative Arms .936 Adjustable Gas Block

- Aero Precision Stainless Rifle-Length Gas Tube

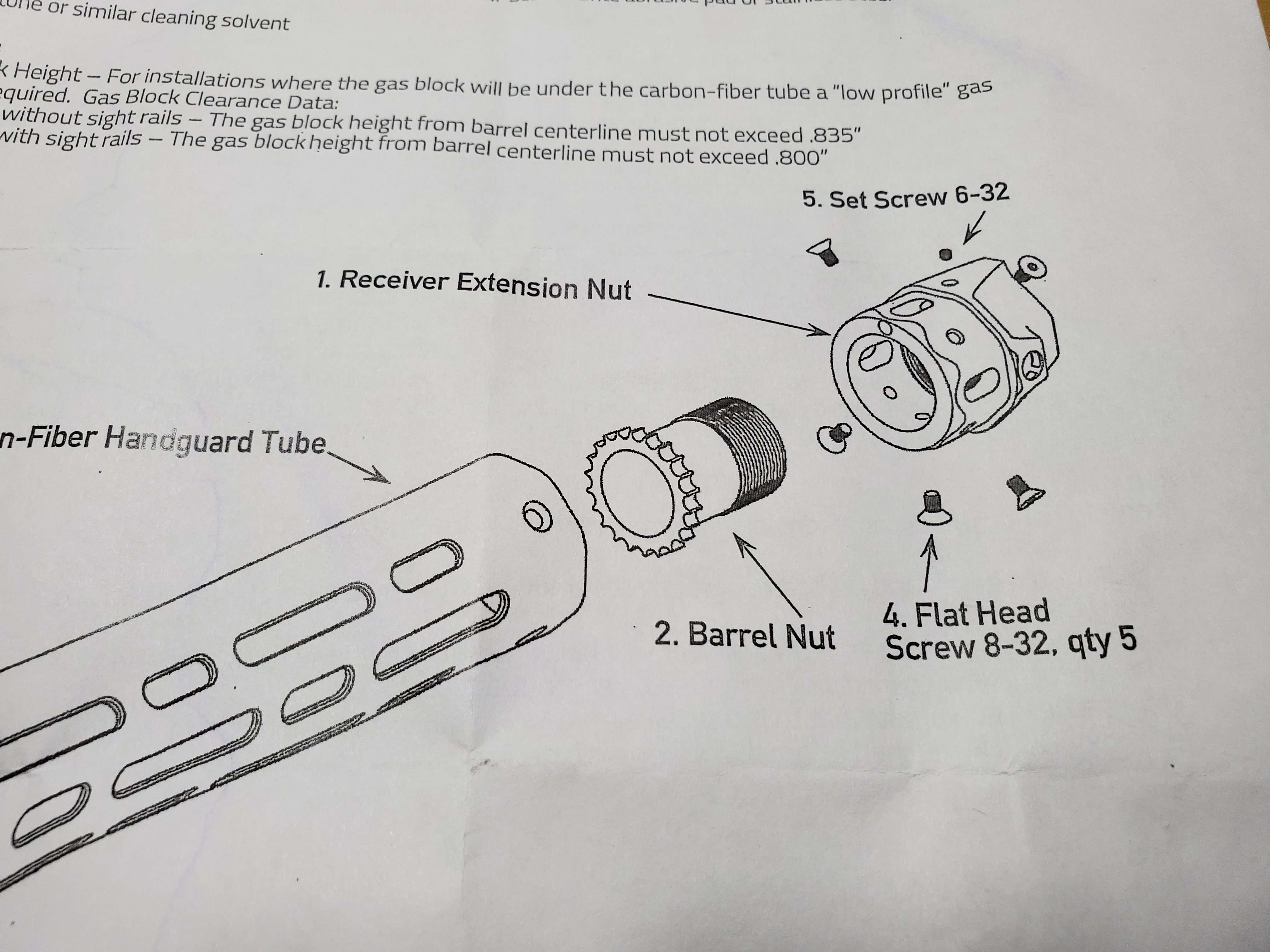

- Lancer LCR5 16.25" Carbon Fiber Handguard

- Magpul Bipod

- Maxim Firearms 6.5 Bolt (matched & headspaced by Lilja)

- AAC (Toolcraft) Nickel Boron Bolt Carrier

- TriggerTech Adaptable AR Primary Trigger

- Strike Industries Cobra billet aluminum trigger guard

- Rainier Avalanche Mod2 Charging Handle

- Aero Precision AR15 A2 Rifle Buffer Kit

- Magpul PRS GEN3 Stock

- Ergo Tactical Deluxe Grip

- Vortex Razor HD II 4.5-27x56 Rifle Scope

- Geissele Super Precision 34mm AR Scope Mount

Thanks to Vortex's generous 40% discount for First Responders, even with the tools I needed to buy (bench vise, blocks, punches, torque wrench, armorers wrench, Reaction Rod) plus four E-Lander magazines and a Pelican 1750 to tote this thing around, I was able to stay under $5000. Now the fun part...I get to put it all together

Comments welcome.

).

).

Comment