Barrel Nut Torquing?

Collapse

X

-

NRA Basic, Pistol, Rifle, Shotgun, RSO

CCW, CQM, DM, Long Range Rifle Instructor

6.5 Grendel Reloading Handbooks & chamber brushes can be found here:

www.AR15buildbox.com

Comment

-

-

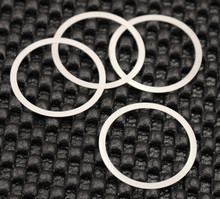

I use barrel shims, they are quite easy to use..

You need to make sure you grease the the threads as 52 explained.

Lightly grease the front of the barrel flange the shims rest against (between the barrel flange and barrel nut face) front side.

Be sure to lightly grease both sides of the shims.. Installing shims dry can damaged them during the barrel nut torque process..

Comment

-

-

Scotty,

Unusual that in 18-80lbs a gap does not line up for the gas tube. I have heard of people going to 85lbs but don't go any higher or the aluminium will start to deform.

For something as important as the barrel-receiver interface I would stick carefully within the recommended range 35-80lbs. I cut off a tooth once and it worked. You don't need all 20 teeth to get the barrel nut on and off, and they are only there to aid assembly. One missing tooth will do absolutely nothing to anything, except let you fit that gas tube properly. Plus, you won't see the missing tooth once the handguard goes on.

As for what torque, 35-40lbs is what manufacturers of non-teeth handguards are recommending, but not less than 35lbs - and definitely not 18lbs.

Comment

-

-

DetailsA crooked handguard does more than just look bad, it can impact your accuracy and make it difficult or impossible to zero laser systems. Make sure your handguard is perfectly aligned with the Aero Precision AR-15 barrel nut shim pack. Each pack contains eight stainless steel shims that will allow you to perfectly time your barrel nut so you can ensure that your handguard is perfectly aligned with your receiver. These shims are designed for use with Aero Precision's BAR barrel nut and freefloat handguards and will not work with the standard MIL-SPEC barrel nut. Don't let a crooked handguard hold back your build!Features:Stainless steel8 shims per setCompatible with Aero Precision's free float barrel nutsNote: Not compatible with MIL-SPEC AR-15 barrel nuts.See More

Having to spend a little over $5.00 for barrel shims to properly torque and align the barrel nut is worth it to me, instead of doing a bubba job and mangling the barrel nut on a $300.00 + carbon fiber hand guard, but hey, that is just me...

Comment

-

-

Be sure when facing (lapping) the front of the receiver the barrel extension feed ramps don't extend too far over the uppers feed ramps or you will need to do barrel feed ramp work...Originally posted by BlogSarge View Postadd another vote for facing the front of the receiver to assure it is square. This could gain you the needed extra bit of rotation of the barrel nut.

Comment

-

-

It's not about the cost of shims. It's about the fit between the barrel extension flange and the receiver. I wrap extensions with stainless stock to achieve a press fit between the extension and the receiver tube. From tearing down uppers and reassembling them, I find this improves accuracy by about .25 moa. I don't care what the barrel nut looks like under the handgaurd. Based on my experience, I would not want a shim between the receiver face and the extension flange, if I could avoid it. I would rather cut off a tooth. In fact, I prefer handguards with nuts that don't have to be timed for this reason. For what it's worth, I have rifles that have shims between the nut and the receiver, but I prefer otherwise. YMMV.

Comment

-

-

The shim does not go between the upper's receiver face and barrel flange, it goes between the barrel flange and barrel nut..This is why it is important to grease the front of the barrel flange and shims..Originally posted by Bonas View PostIt's not about the cost of shims. It's about the fit between the barrel extension flange and the receiver. I wrap extensions with stainless stock to achieve a press fit between the extension and the receiver tube. From tearing down uppers and reassembling them, I find this improves accuracy by about .25 moa. I don't care what the barrel nut looks like under the handgaurd. Based on my experience, I would not want a shim between the receiver face and the extension flange, if I could avoid it. I would rather cut off a tooth. In fact, I prefer handguards with nuts that don't have to be timed for this reason. For what it's worth, I have rifles that have shims between the nut and the receiver, but I prefer otherwise. YMMV.

Putting the shim between the upper receiver and barrel flange can change the lock up timing/indexing, gas tube depth into the gas key and create other problems..

I assumed this was common knowledge. This is what I get for assuming things..Last edited by montana; 03-13-2023, 03:15 AM.

Comment

-

-

Originally posted by montana View PostThe shim does not go between the upper's receiver face and barrel flange, it goes between the barrel flange and barrel nut..This is why it is important to grease the front of the barrel flange and shims..

Putting the shim between the upper receiver and barrel flange can change the lock up timing/indexing, gas tube depth into the gas key and create other problems..

I assumed this was common knowledge. This is what I get for assuming things..Last edited by Klem; 03-13-2023, 06:38 PM.

Comment

-

-

Mangling a barrel nut when not needed is not considered quality work where I'm from Klem, but people do have different standards.. If you purchased a new rifle and the manufacturer ground off one of the keys to reach torque spec I'm sure you would be A-OK.. I wouldn't be, I would ask for a refund....

I did watch that video a while ago before they turned off the comment section for a reason.. Putting shims between the upper receiver and the barrel flange, is doing it wrong..

I know all about your opinion on quality work, such as shooting questionable loads from behind a tree, sand papering the boat tail to remove carbon and grinding out the aluminum upper receiver feed ramps while simultaneously removing the hard anodizing in the process..

One thing I do know is there can be a lot of contention between AR building procedures between the so called experts..I know I don't agree with any of them 100% of the time, even those I respect the most.... I just take it with a grain of salt when certain people get triggered by mine or other peoples opinions..What I call Bubba work you and others may consider top notch gunsmithing.. That's whats great about the USA, having an opinion and the right to choose who we listen to..In either case it is no skin off of my teeth what you or others do with their rifles, I'm not in a popularity contest or care what the latest consensus is..People ask for opinions and I give them mine.. They can choose who they wish to listen to or not.. Have a great day Klem..

Comment

-

Comment