I need a mid length gas tube for a build that I'm getting ready for but I don't have one. Am I able to modify a rifle length tube? I was thinking about cutting it down but didn't know if I was wasting my time. I was thinking that the cut end might need to be flared a bit. Any suggestions?

Rifle length gas tube?

Collapse

X

-

Creating a concentric gas tube flange that will seal in the carrier key is the problem. Check the EE on AR15.com if you can't find one, and here:

-

-

Midway had some in stock, I just ordered one.

sigpic

Comment

-

-

I 'borrowed' the one from my BCM 5.56 upper last week to finish my build with 18" AA barrel... I called around town today and thought I had one... went there to pick it up and they had a dozen or so ... (but they were rifle length... not mid... evidently, no one measured them when I called)

Anyway, I was about to head out and see if I could find one on line and just stopped by to chat with one of the other guys that works there and he said he has cut them down on several occasions with no problems. So I bought a couple of them and returned home.

I needed to cut it down from ~15" to 12"... so i straightened out the bends (as the cut had to happen right in between the bends) by drilling a hole the same size in a 2X6 and mounting the tube in a drill chuck... then I carefully pushed the tube into the hole at a low rpm... pushed it on through and increased the rpm while running the tube in and out of the wood block until it spun without wobbling.

Then, using my dremel cut off, I chopped it to 12" exactly... and finished the end nice and smooth.

Then I had to make the new bends ... I did that by using the same 2" piece of wood I used to straighten it. I pushed the tube in to where I wanted to make the bend and carefully made the bend... pulled it out and inserted the other end until it hit my mark and made that bend...

When I put the tube in the upper, the bolt didn't want to cycle really smooth... so I kept taking it out and making small adjustments to the bends until the bolt cycled smoothly.

I haven't taken it to the range yet, but will report back here when I do...

It seems to fit just fine... only thing I noticed is what looked like a slight flare on the bolt end of the tube (before cutting it off) was actually about 2 inches of machining done to that end of the tube about 1/8" inch in from the end. I didn't do that as i didn't have the tools to actually do the machining. If anyone's interested, I can post a pic or 2 of the other one I bought so you can see what I am talking about...

Comment

-

-

Some Pics of my 'hack job'...

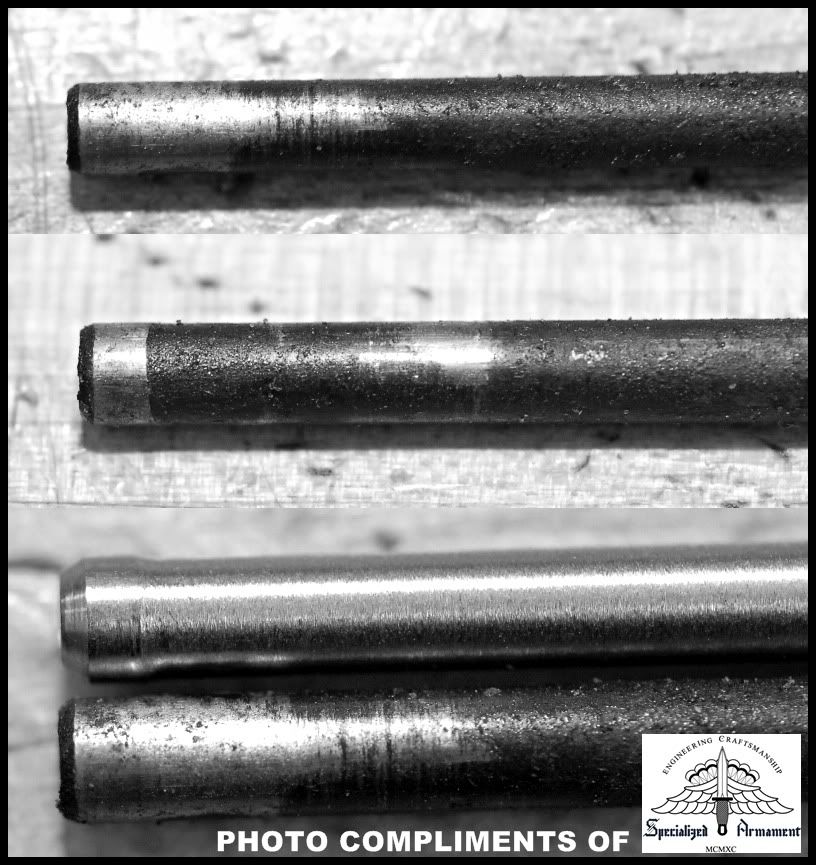

Here are a couple pics of the end I cut off the 15" tube to make it fit mid-length...

As you can see, the tube is machined down .010 starting about .125 in from the end and continuing for 2.20 inches...Not really a flange by my definition... just that the machined portion is .010 smaller in diameter than the end that goes in the key...

As I mentioned before, I didn't have the capability of machining the tube down like that, so just left it at .179 thickness...

I may be able to test it in the next day or 2 or maybe this weekend... I will be ordering the correct one for it, but will definitely leave it in place for a while to see how it performs.

Thanx to LRRPF for pointing out the fact that a worn tube will definitely cause some problems... All the more reason to make sure the tube is nice and straight and does not bind going into the key...

thanx,

Allan

Comment

-

Comment