Hunting knives and related projects

Collapse

X

-

-

Selecting your blank.

A big difference in value and cost is atributed to the various log cuts that become rifle blanks it the beauty of the blank is often very much in the buyers so is a very personal choice. A board or flat cut blank is generally a stronger cut in that there is the longets grain structures and the colour and graining that may be less than spectacular in the full blank may come alive when the shaping is done and even those blanks that are on the verge of being rift cut can have some very good appeal as well. A little more care needs to be taken when selecting a rift cut blank though as the quartering grain may run out in the wrist area and the forearm can cause uneven stability. A quartersawn blank is more often taken from the straight grained part of the tree and while it can provide a very stable stock there is often much less in the way of grain patterns with the dark and light stripes of the anular rings more in evidence.

There are a numbers of areas where grain flow is very important in the rifle stock especially where a heavier recoiling rifle may be concerned. This is ,where the board sawn blank really shines but the grain flow in the wrist and the forearm must be a high priority and the flow into the toe is where it really needs to be following the bottom line of the stock especially if a steel, horn or other inflexable type of butt plate is to be used, as a heavy blow on the toe of the butt plate can cause the stock to break away through this area in some cases. The cartridge the rifle will be chambered for and the style of hunting the shooter intends and his monetry reserve will have the deciding influence in the choice of the blank, however it must be stated that in the heavier recoiling rifles that fancy grain must be of secondary importance to the grain flow to withstand the recoil stresses.

These are examples of some of the finest stock blanks and they will cost immeasurably more than a plainer blank that may very well make into a superbly strong rifle for a big bore and may indeed be more desirable for that purpose. A plat sawn blank that runes straight and true along the top edge of the blank and runs through the wrist is the best option for all heavy rifles. Lighter recoiling rifles can be stocked is very pretty wood that may have less desirable grain flow .

Comment

-

-

Balance and handling

A balanced rifle is one that regardless of the weight, (having the greater felt portion between the hands) and the stockmaker, in conjunction with the gunsmiths barrel length and profile choice, will make the stock to achieve this end with judicious shaping of the various portions of the stock , working toward having a rifle that is an apropriate weight to mitigate the recoil of the cartridge the rifle is chambered for, while endevouring to have the rifle feel well balanced so that is has good handling and pointing capabilities regardless of the finished weight. Of course the barrel profile and any action work with intended sighting devices included will all have been selected at planning time with a final goal in mind so the weight of the stockwood can have a dramatic effect on the expected total. Many have found a well figured piece of dense walnut may add a lb or more to a stock so the choice of the blank is probably one of the more time consuming decisions that needs to be made. The weight and the balance are two of the factors that go toward the handling characteristics of a rifle.

As noted above, the focus of this piece is a well balanced, quick handling hunting rifle, so after the initial dimensions of the LOP, comb line, pitch and cast are decided on there are other important dimension to be taken into account that effect the balance , the weight and ultimately, the handling of the rifle.

Of course the barrel profile will have a dramatic effect on the balance and handling of the rifle but it will also play a role in how the recoil is enacted against the shooter. A 9 to 10 lb rifle that recoils in the over 50ft lb of recoil range, may be from very comfortable, to very undesirable to shoot, depending on where the weight is situated.

If we take the natural handling balance point to be at the forward action bolt (or within an inch of it either way) with the magazine filled, so that when the rifle is held in a shooting position, with one hand gripping the wrist and the other the forend, they will be almost equally spaced either side of the balance point and this promotes desirable handling atributes. The old English makers aimed to have 60% of the weight between the hands and worked a compromise between barrel profile, stockwood density and shaping to achieve this. Splinter forends, cheekless combs, elegantly thined wrists and narrow butts were all measures made to bring a balance to the particular rifles handling needs dependant on the cartridge being chambered.

A light barrel on a heavy stock with the weight centered behind the handling balance point, even back as far as the rear action bolt, will allow the barrel to rise very fast and cause the comb to slap the face. This also effects handling as while the rifle will swing very quickly onto target, it will be much more difficult to hold steady, especially if you have been walking hard or uphill and might be blowing a bit.

If on the other hand, the barrel is a very heavy profile, the weight may be centered much further forward, maybe even up to 6 inches ahead of the handling balance point. This will make the rifle very muzzle heavy and much slower to get started on, and stoping a swing coming onto the target. Muzzle rise will be reduced in recoil but without the natural balance between the hands the butt is not as secure and can move under recoil.

These areas will greatly effect the final stocks handling ability.

The grip curve and the relationship of the trigger finger to the trigger.

The circumference of the grip.

The length and circumference of the forend.

Thickness of the stock through the various parts of the stock.

For anyone contemplating having a stock made or making one for themselves there is no "formula" that will get a good fitting stock as there are so many variables in shooting stance, body conformity and comfort ideals and so there is an experience quotent needed in the setting out of the stock.

The first line to be drawn on the stock blank is the bore line and as this is also the top edge of the forearm, is the datum from which all other lines and measurments are taken. I like to have a pattern drawn of the intended stock on sections of 1/8 in ply or similar and place the pattern on the blank to make the best use of the grain structure in the forend back through the action and into the wrist, although the toe of the stock needs attention to grain direction if all weaknesses are to be avoided. Some have their patterns on clear perspex so the grain lines can be seen. The grain in the top of the stock needs to be checked to make sure it runs true to the line of the stock rather than diagonally across the stock which leads to weakness and or warping danger at the very least. The ends of the stock will give more information as to the grain direction with either verticle or horozontal showing flat or quarter sawn. Try to stear away from a rift sawn blank and any one that has grain lines running out anywhere through the wrist (either on the top or the side)

When the pattern position is established and the bore line is marked it is best to then dress the stock so that the boreline then becomes the top edge of the stock. Now with the pattern in place the trigger position should be marked in conjunction with the grip curve and from here the action screws can be marked which then dictates the action markout and so the inletting can begin.

Comment

-

-

Stock inletting and shaping

Stock inletting.

Wether by hand or machine, the barrelled action needs to be fitted down into the stock blank. Here we concentrate on hand work and so a colletion of very sharp chisels and scrapers are required. The larger volume of wood removal can be augmented by carefull drilling, preferably with a drill press to keep things square to the top line and from where the stock is rested as the drilling for the action screws are made, along with the mag well prelinary removal that is finished with chisel and scraper. Anyone contemplating doing this work should have a clear understanding of wood working methods as this is not the place to learn care and control of these tools and how the grain of the wood can have varying degrees of cutting ability with the potential for spliting, chiping and other possible stock destroying results of careless work. Slow and carefull is the only advise that can be offered with the liberal use of a smoker (pics of smokers), inletting black or other action marking methods so the marked areas can be attended to. Care needs to be taken to check for draft on the vertical areas of the action, with draft being a minor widening of the metal as it seats into the wood to ensure a tight wood to metal fit on assembly. The barrel channel can be opened up with special barrel channel rasps or it can be carefully rough cut by chisel and then coarse sand or emery paper wrapped around various sized dowels can be used till it is close then finer grades of paper untill there is either a tightly fitted or floated barrel to chanel clearance.

The inletting is a particularly important part of the building process, simply because the accuracy of the finished rifle will depend to a large extent on how well the barrelled action nestles into its stock. There is tradition that says it should look as if the metal has grown out of the wood and while this is a laudable intent, there are places where there needs to be clearance to ensure the prolonged integrity of the rifle.

For a heavy recoiling rifle there needs to be clearance around the rear of the tang, and any pillar between the tang and the bottom metal needs an oversized hole for the action screw so that the pillar is not driven rearwards (potentially causing spliting into the wrist) due to the wood sourounding the mag well flexing as the action, locked into the stock by the recoil lug tries to drive back to the rear.

The recoil lug needs clearance at the sides and to the front to facilitate the easy removal of the action from the stock.

There needs to be clearance around the barrel from the chamber forward with everything else fitted tight and true. If a forend tip is required the forarm is cut to the desired length and the block of buffalo horn, ebony or other exotic wood is doweled and glued into position before the final barrel channel work is done.

Shaping is the next most important part of the process. Obviously the understanding of the previously discussed design paremeters in the form of the length of pull, comb and heel drop, pitch and cast both at the heel and toe if required, have been drawn into the outline. The grip cap and recoil pad is marked into position and fitted so that their outline can determine the shape of these areas and with plane, rasps, files, chisels and various grades of sand paper the desired finished shape is bought into the light of day. This is where the knoweledgable stockmaker may make subtle adjustments to the various areas of the stock to get the balance spoken of above that will bring the handling characteristics that are so desirable in a stalking rifle.

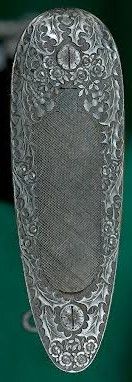

There are many different aproaches to the butt plate-recoil pad and from full steel plates to toe and heel caps, the variety is only limited by the purpose the rifle will be put to and the level of recoil that needs mitigating.

From plain to fancy and solid to skeletonised.

Comment

-

-

Comment

-

-

Comment

-

-

Comment

-

-

When everything is as it should be, the finishing can be contemplated and it needs to be on a surface that has been sanded down with a wet and dry paper graded at least in the 400 and preferably in the 600 grit range.

The stock is then wetted with a cloth dippedinto a bowl of hot water and left to dry so that for the whickering process to lift any fiber ends that are then sanded off again with the 600 grit paper. The wetting and whiskering needs done at least twice and depending on the density of the particular wood being worked on, may need doing 3 or 4 times until the wetting raises no more whiskers.

There are many different ways of putting a finish into the wood surface to ensure that there is no water soakage possible and any atmospheric humidity flucuations are not going to be able to migrate into the wood causing swelling, warping and accuracy issues.

All surfaces must be treated an the grip cap and butt plate or recoil pad need to be removed for this to be accomplished.

The various comercial finishes will come with their own instructions but I prefer the time tested pure tung oil. The oil is cut 50/50 with vegetabe turps and the stock is swamped with this mix every 5 minutes or so until the uptake slows down and then after another 15 minutes I wipe the stock down hard with a lint free cloth. Left for 24 hours the same 50/50 mix is then rubed into the stock using 600 grit W&D paper and it goes without saying that following the grain with nthe paper is how this is done. This creates a light slurry on the surface of the stock and this is rubed in, in a circular motion with the bare hands and again after 15 min to a half hour the cloth is used to lightly wipe off the excess.

This precess is repeated daily untill the pores are all filled and then the stock is rubed back down to the surface with the fine W&D.

Now the actual finih is applied using the undiluted pure oil and is done by putting a few drops into the hand and rubbing it into the wood. The less is more certainly applies in this operation and rubbinh briskly to create warmth and leaves the surface with just the faintest wet look.

Again this needs doing daily but the purpose is the have the oil in the wood rather than on the surface.

There is a tradition that says you need a coat a day for a week, and coat a week for a month, a coat a month for a year and a coat a year for life. I have found on the few good quality walnut stocks I have been priveledged to build I have done the first 7 or 8 coats on a daily basis and then every two days after that for up to 20 coats with the lasy coat rubbed with a coarse cloth so that there is a low sheen or eggshell lustre to the wood with a depth of colour that is a treat for the senses. Patience is required and amply rewarded.

Comment

-

-

-

Comment

-

-

Comment

-

-

Comment

-

-

Thank you Von Gruff for posting this very informative information. I never quite understood all the different blank cuts, strengths and weaknesses of all the different woods, grain patterns until now. I have read about having a rifle fitted to an individual but never quite understood the whole process until now. The farther I go the more I realize how little I knew or thought I knew about stock making. It reminds me of the first time I shot my first customized handgun in competition. It didn't make me a better shooter, but what a difference. A person can never understand or appreciate what it takes to create such a work of art until they know the process. It takes a special kind of person to be a good stock maker, instant gratification seekers need not apply! I have a special weakness for rifles that shoulder quickly since I was brought up snap shooting at Whitetail deer and they usually only give you one or two jumps before they disappear. My rifles had to be fast to shoulder or I would go home skunked with my tail between my legs LOL. I would be admonished by my father if I missed or made a poor judgement on a shot and rightfully so. It made me a better shot. Life is good

Comment

-

-

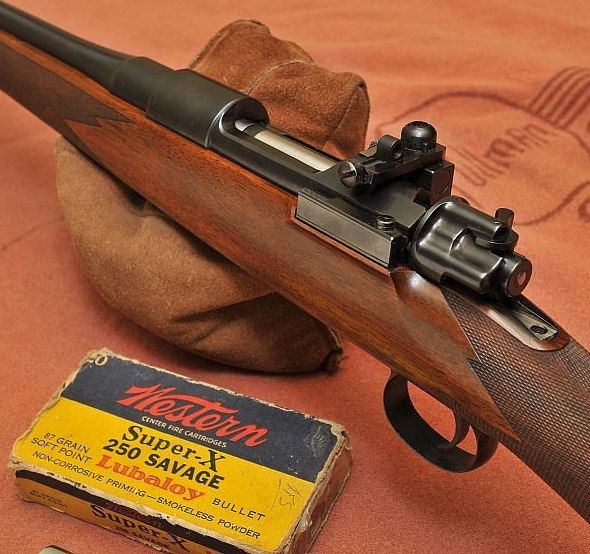

One area that many current factory and or replacement stocks fail for a stalking rifle is in the fat and overly long forend and because a stalking rifle should be in hand when stalking any carry strap (for after the hunt) atachment could/should be on the barrel so that the forward hand can grasp the forestock and close over it with the fingers resting against the barrel. This puts the center of the barrel closer to the palm and enhances the pointability of the rifle.

This is how the stock should be able to be held with the index finger acting as the pointer.This pic is of my 400 Lee Speed which has a barrel that is .8 at the end of the forend tip so you can see how slim the forestock is to be easy handling and to complement the balance of the rifle.

The forestock is just 1.25 and the transition of the walnut/ebony tip.

Last edited by Von Gruff; 01-31-2017, 06:22 PM.

Last edited by Von Gruff; 01-31-2017, 06:22 PM.

Comment

-

-

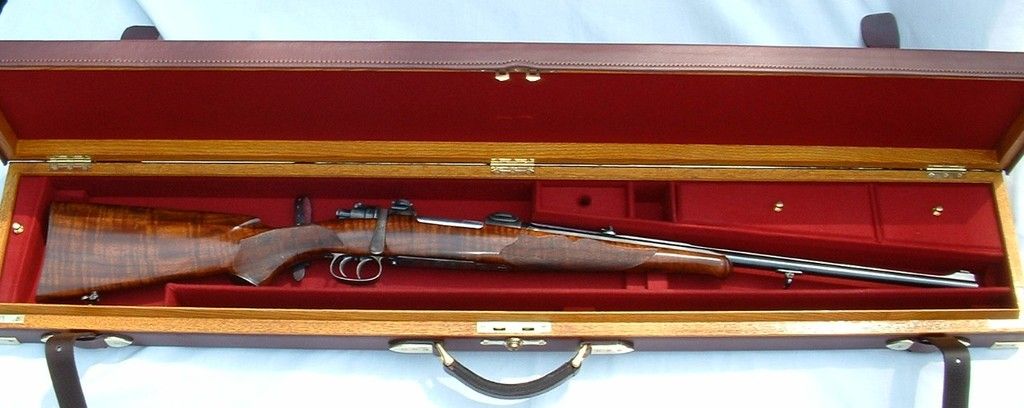

Bills Lee Speed

After the recent thread on the Lee Speed disease that Bill admitted to suffering from, discussions were held on a cure and it was decided that a project would be started to make a Lee Speed styled sporting rifle from an apropriate action. So the first thing was to source a base rifle to work from and an 1893 BSA & Co MK l was bought from the local auction site. It was not a candidate for restoration as the stock had been cut off ( it was quite rough along the forstock) and there was only half the forward part of the lobbing sight and no rear part. The mag cutoff was missing (but I have one to add) so it was a decent base to work from. It has a nice NZ mark on the left receiver ring where these are often quite haphazardly marked so that is a nice touch. Mismatched bolt and action numbers so I didn't feel it was taking an original out of circulation.

The mid barrell band is there but I had it off to check the metalwor below the stockline and it wont be going back on anyway.

A selection of stock blank pics were sent and Bill selected this one

Comment

-

Comment