Those came out beautifully. Your designs look very practicle and I especially like the Red G handle with the brass pins. Larger blades are much harder to make than smaller ones but you did an excellent job on the slicing knife. Your handle work is as good as I have seen. Well done!

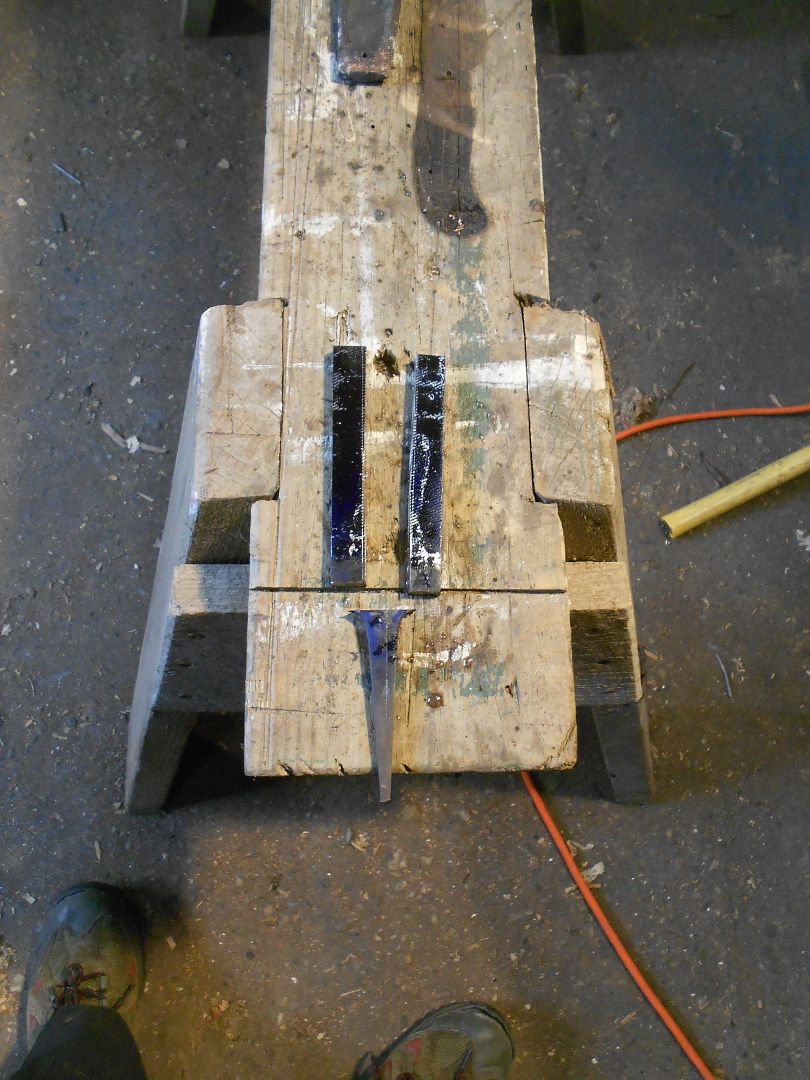

I have to confess the first time I saw the picture of the saw horse in your house I cringed thinking what my wife would have done to me if I had done that. My wife would do a bonkers if she new what I have done with our oven and a few other things in the past. Some things are best kept a secret LOL

I have to confess the first time I saw the picture of the saw horse in your house I cringed thinking what my wife would have done to me if I had done that. My wife would do a bonkers if she new what I have done with our oven and a few other things in the past. Some things are best kept a secret LOL

Comment