Hunting knives and related projects

Collapse

X

-

-

I put it together just to see how it looked

Then it was the turn of the butt plate so it got marked out and the beak inlet

And then the start of some shaping began but the day had been long enough that a rudimentary shape was all I got it to.

I forgot to take a pic when I did it but the lever cup was fitted when the butt stock was still in the square

Comment

-

-

The first chore today was to fit the barrel band attachment for the forestock and as it was smaller in inside diameter than needed to get as far up the barrel as the forestock dimensions required. A piece of 220 grit wet and dry was wrapped around the barrel with the band over it and by working it back and forward and having many tries I was able to increase the I D.

Still a way to go as I wanted it to cover the main pin hole for the original rear sight . ( this is a good take-off smle barrel) The cross barrel pin hole can have a pin driven in and dressed off later on.

Having marked where it was to go to on the barrel and transferred the marking to the forestock it was time to remove a little wood

Comment

-

-

With the band fitting into the forestock I could drive it onto the barrel. A good clean and a light smear of Imperial sizing wax was enough to help get it up to the desired point where it is a very tight no slip fit. It took a little to drive it the last 1/2 mm but a brass block and going round the band got it sorted. Of course I did set a level on the action bottom to get it right in the vise and then checked the bottom of the band nut to make sure as I went forward.

The machine screw that had been with it needed a little shortening and the back of the head re-shaped to mate with the counter bore in the forestock but eventually it all came together.

Comment

-

-

The rest of the day was taken up with shaping the forestock

And finishing the butt stock shaping, with it all sanded to 100 grit

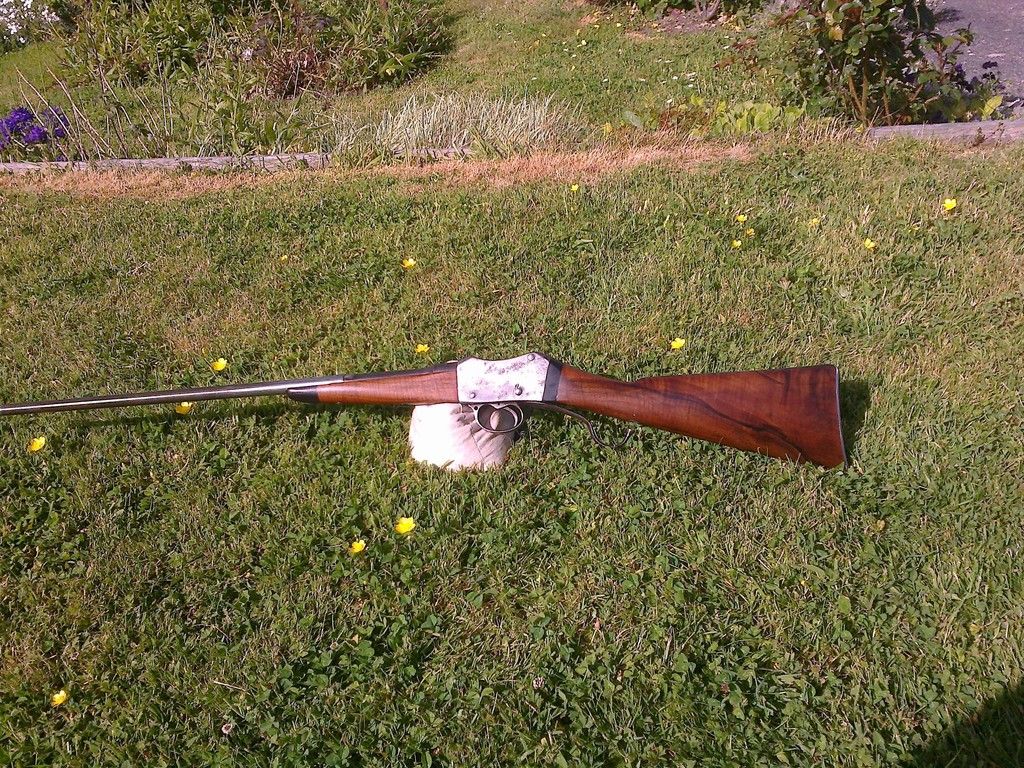

At this stage it will wait till Euan can have a check fit as the brief was to make this a slim trim sporter and putting it on the scales it tips them at 6 lb 1 oz with the only addition to be a set of open sights and a barrel band sling eye (half way between the forend tip and the muzzle) so it will probably not go over about 6 lb 3 or 4 when finished. The grain in this one is quite spectacular as the full fiddle back in the forestock runs back down the wrist of the butstock where it reduces and straightens into the dark and light pattern. With some alkanet and oil it will be quite striking.

At this stage I should post one of the very many that were bought down on a thumb drive to show me what the ideal would be and at least to my eye I think I am about as close as I can get going off a picture.

The one thing I did do differently to the pic which was discussed at planning stage was to lengthen the wrist so tat I could leave off the comb fluting. If you check the latch end of the lever in the sample pic , you can see that the lever end is behind the comb nose which can crowd the hand and so the sporting version have the fluting the relieve this area. By lengthening the wrist the fluting becomes superflous. I have a suitable piece of buffalo horn which I will suggest to Euan for the forestock tip but he often prefers them plain. Will see him at the weekend so will know then.Last edited by Von Gruff; 01-23-2017, 07:04 AM.

Comment

-

-

He called in today and we discussed )among many other topics) the buffalo horn forend tip and so that is going to be attended to next

Nothing quite like cutting the end off a fully shaped forestock to add the tip for making you very carefull of measurements etc

Normally I have three brass dowels to hold the tip on but this forestock is so slim that I only really had room for two. The 1/8 in brass dowels are bruised with a set of end nippers to make them a bit more grippy and the epoxy is mixed with a touch of black concrete die to match the the horn tip after it is polished just in case there is any imperfections in the mating surfaces

All clamped up where it will sit for a couple of days while I do other "stuff".

Comment

-

-

A few hours this morning had the raw horn shaped back to where the old tip had been

With tape around the end of the file I can make sure that I am keeping things from getting down past the original bed. I keep the taped end in the barrel channel but had to sit it like this so it would balance for the pic.

So back to a 150grit finish at this stage.

Last edited by Von Gruff; 01-23-2017, 06:44 AM.

Last edited by Von Gruff; 01-23-2017, 06:44 AM.

Comment

-

-

Comment

-

-

This one is my latest and one that is going to be a keeper. Probably the most interesting and complicated to date with some of the design needs.

It seems like there may well be a new project in the offing. There has been a trade agreed where I send a Mk 1 Long Lee Enfield action to a feller and he will send me a 1916 Kar 98 small ring Mauser action.

Being a small ring it can be made into a nice light hill rifle and I have decided that a 6.5x57 in a blind mag stock designed for open sights will be the way to go with this one even though I will possibly look at a QD scope as well. This is going to have a ring of the 1920's to it or that is the way I see it in my head.

It may well be a few weeks before the action arrives but I thought to get the stock design sorted now and thought that I might do a trial one first to get the blind mag area understood before I attack a nice piece of walnut.

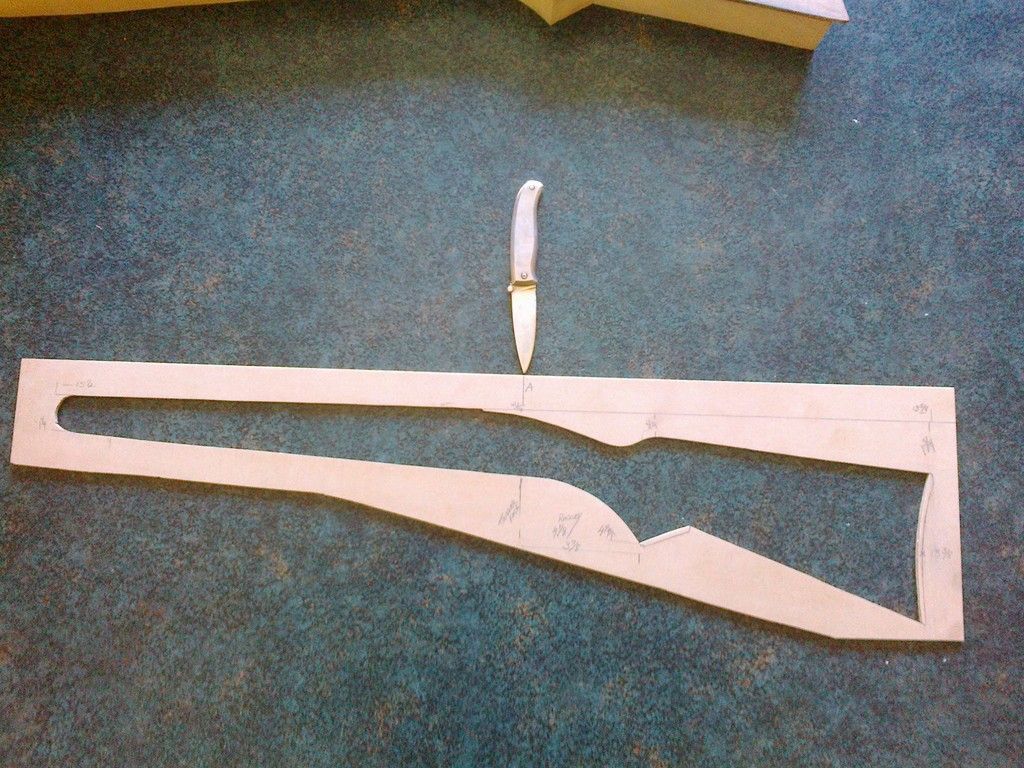

To that end I drew out the plan and cut both a pattern and a framed pattern then a trial stock from a piece of Rimu and thought that it may be of interest to look at how to draw out the pattern.

Comment

-

-

I used a piece of thin board that is 8 1/2 in deep for the framed pattern so I could get all my measurements noted down.

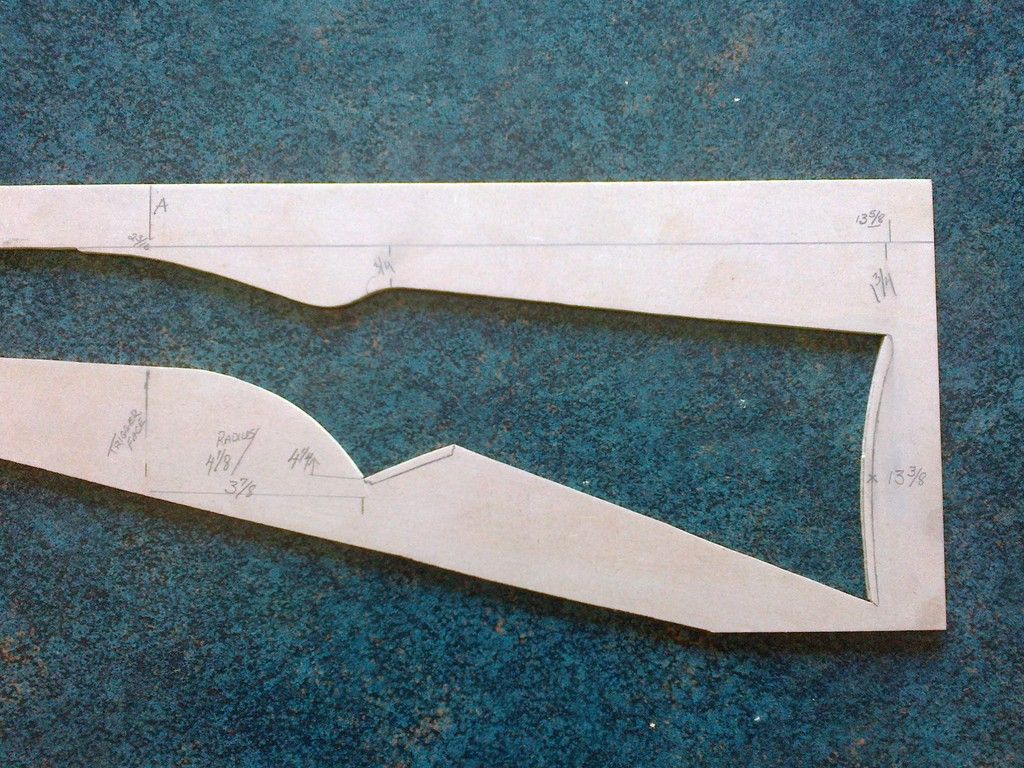

I started by marking a line the width of my long steel rule (1 1/8) parallel to the top so that when I cut out the interior there is enough strength left outside it to hold it all together. This line is the stock top line and all measurements noted are down from this line. Point A is marked in along this top line and to find point A --- I made my stock to have a 13 3/8 L O P so point A is 14 1/2 in from the butt end of the board. Adjust as necessary for your own desired L O P. I will deal with the forestock first.

From point A, square a line down to the bottom of the board as this is the face of the trigger and where all the measurements go from. From point A mark down the line 2 3/16 as this is the depth of the stock at this point. Measure toward the forend tip 15 1/2 inches and square a line down with a point marked in an 1 1/4 down from the top line. You can now draw a line from this point back through the first point measured down from point A to give you the forestock length and shape.

Comment

-

-

For the butt end I start with the grip curve so to get there I measure back toward the butt from point A 3 7/8 then square down from there. Measure down that line 4 1/4 and mark the spot. ( call it B) Next comes the grip curve and this calls for a bit of try and adjust. Set you calipers for 4 1/8 as this is the radius for the curve and it requires the curve to go through the point B and back into the line we drew back from the forend tip to intersect where the center of of the trigger curve will be directly down from point A. Then you can use your square and mark in the grip cap line back toward the heel. My intersection point is 14 7/8 back along the top line from point A. Mark 1 3/4 for the grip cap length.

Next comes the comb nose and I mark 4 1/2 back from point A and go down 3/4. This is where the comb nose starts to curve down toward the top of the wrist. Mark back from point A along the top line 13 5/8 and down 1 3/4 to the heel and now you can draw in the comb line. For myself I marked down with a 4 degree negative pitch and drew in the curve for the checkered steel butt plate. If you need a longer L O P I would stoll draw in the drop a heel at the 13 5/8 mark and continue the comb line till you reached your desired L O P.

I am going to grind back the steel plate to give me a length of 4 7/8 so from that point I can draw in the toe line of the butt from the tip of the butt plate to the 1 3/4 mark on the grip cap line.

It will be noted that this line (continued) is above the grip curve by 3/16 - 1/4 but this all helps to lighten the appearance of the stock.

Comment

-

-

I made a start on the trial blind mag stock today. I am going to use a altered military trigger where the finger piece is adjusted to the rear by about a 1/4 to bring it closer to the rear of the trigger bow so I took the one off my other 7x57 so I could get the placement of the action on the blank.

Center of the trigger face is the datum point so measuring back to the rear stock screw centre is the first move

Then the front stock screw can be marked in

From these two points the trigger clearance slot can be done and the action sat into the blank on the headless screws to mark in the other data points

And a while later it is starting to settle into the wood.

Comment

-

-

Have the action settled into the wood. I had the stock for my DWM set on the bench as a visual guide and for measurement checks.

I made a start on the jig to allow the use of the router to do the blind mag. I cut a block to fin into the recoil lug and fixed a slow wedge shaped piece to it so the top of the guide was parallel to the bottom of the stock.

Careful measuring of the internal mag dimensions and allowing for the guide collar on the router base required a 1/2 inch over the required size so I should get the correct finished size. I will try it tomorrow on a scrap piece first then one the practice stock. Going to be an interesting trial.

Comment

-

-

have been able to get the practice inlet done after a couple of alterations to the jig and it holds four down and feeds flawlessly. Then the barrel turned up that had been part of the trade for the action. It was a stepped barrel that I had intended to have the steps machined off but it turned out to be a large ring barrel so wouldnt fit the small ring action without turning the thread off and rethreading for the small ring. As it was just 20 1/4 in long, this coupled with the machining needed for the step removal and the rethreading put it out of contention for use so in thinkingnthrough the possibilities I got onto one of the short chambered 6.5x55 barrels from Brownells which I will have shortened a little and rechambered for the 6.5x57.

I got a set of Hornady New Dimension dies in 6.5x57 from Ebay for under US$58 so things are moving in the right direction again.

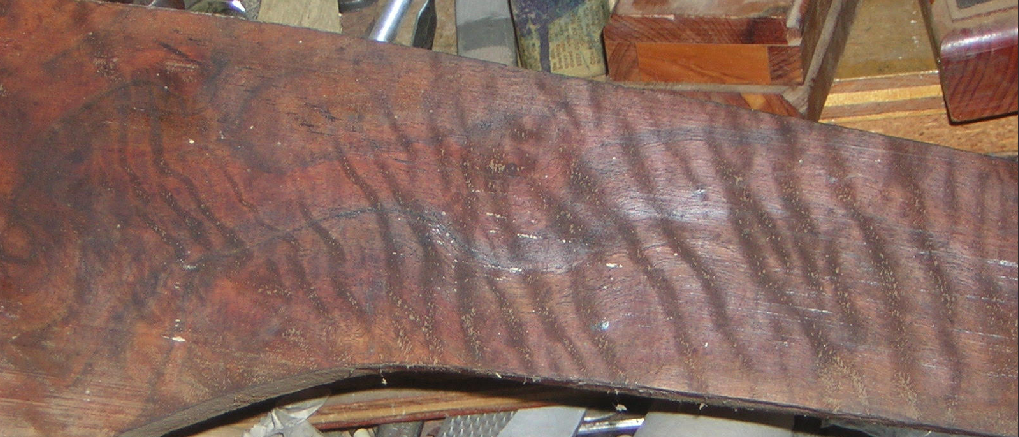

Frank has been exceptionally generous and sent me a lovely blank to build this one on

Comment

-

-

This is the trial inlet on the practice stock. Initially I made the whole well the same depth but then put a fillet in and reset the jig so I could cut the spring end recess. Then I found that I needed the little fillet up the back of the well so it would engage in the rear of the action the same way as the steel tag does on the standard bottom metal. On the good stock I have a little piece of buffalo horn that I will use for this. I make no apologies for the rather rough look to the wood but the rimu is not a suitable stockwood as it has a fiberous texture and tears a little rather than clean cutting like walnut. It was getting the mag well sorted that was important rather than a fanvy finish.

Comment

-

Comment